Small Carving Axe, 0.65 kg (1.43 lb)

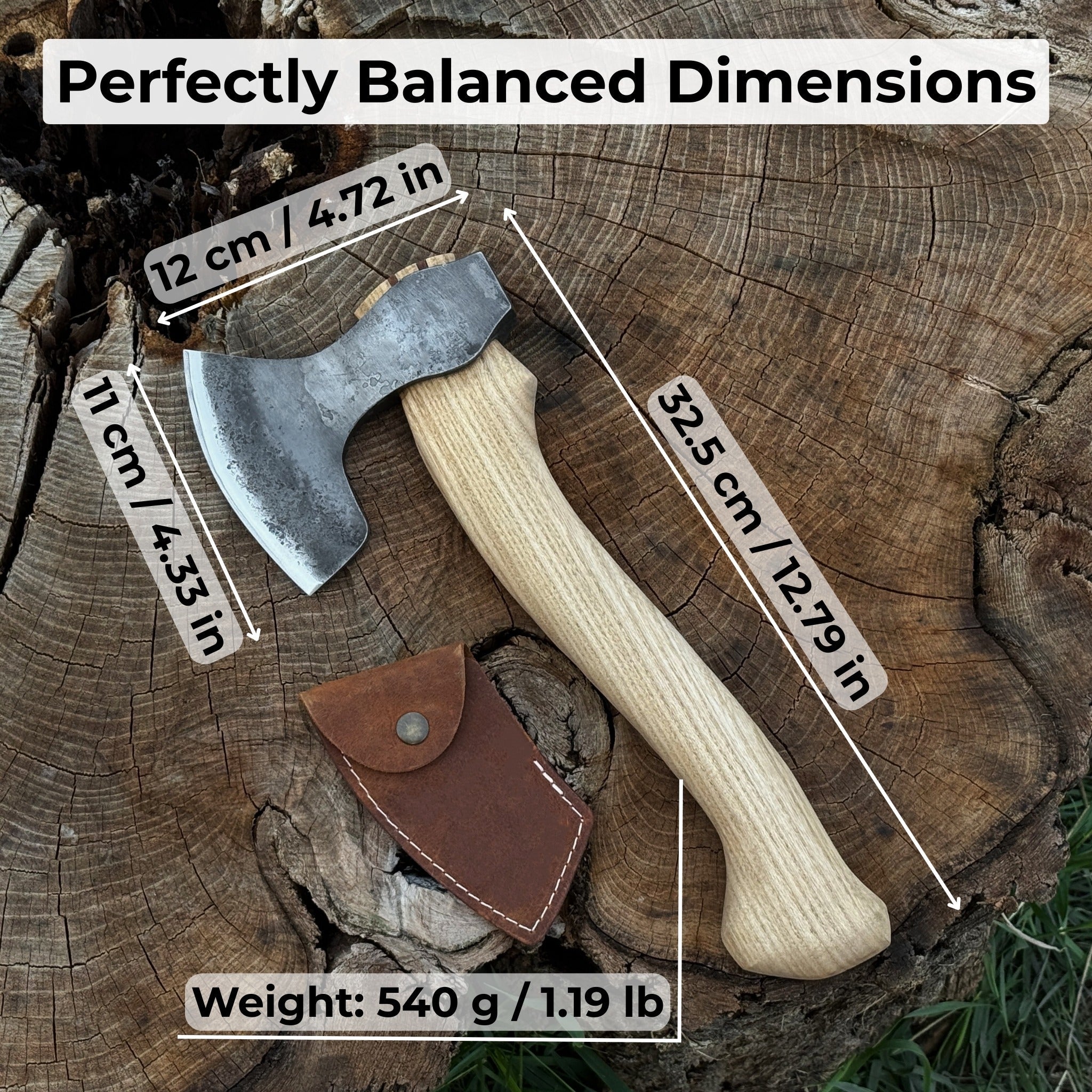

Small Carving Axe, 0.54 kg (1.19 lbs)

Hand-Forged Carving Axe, 1.05 kg (2.31 Ib)

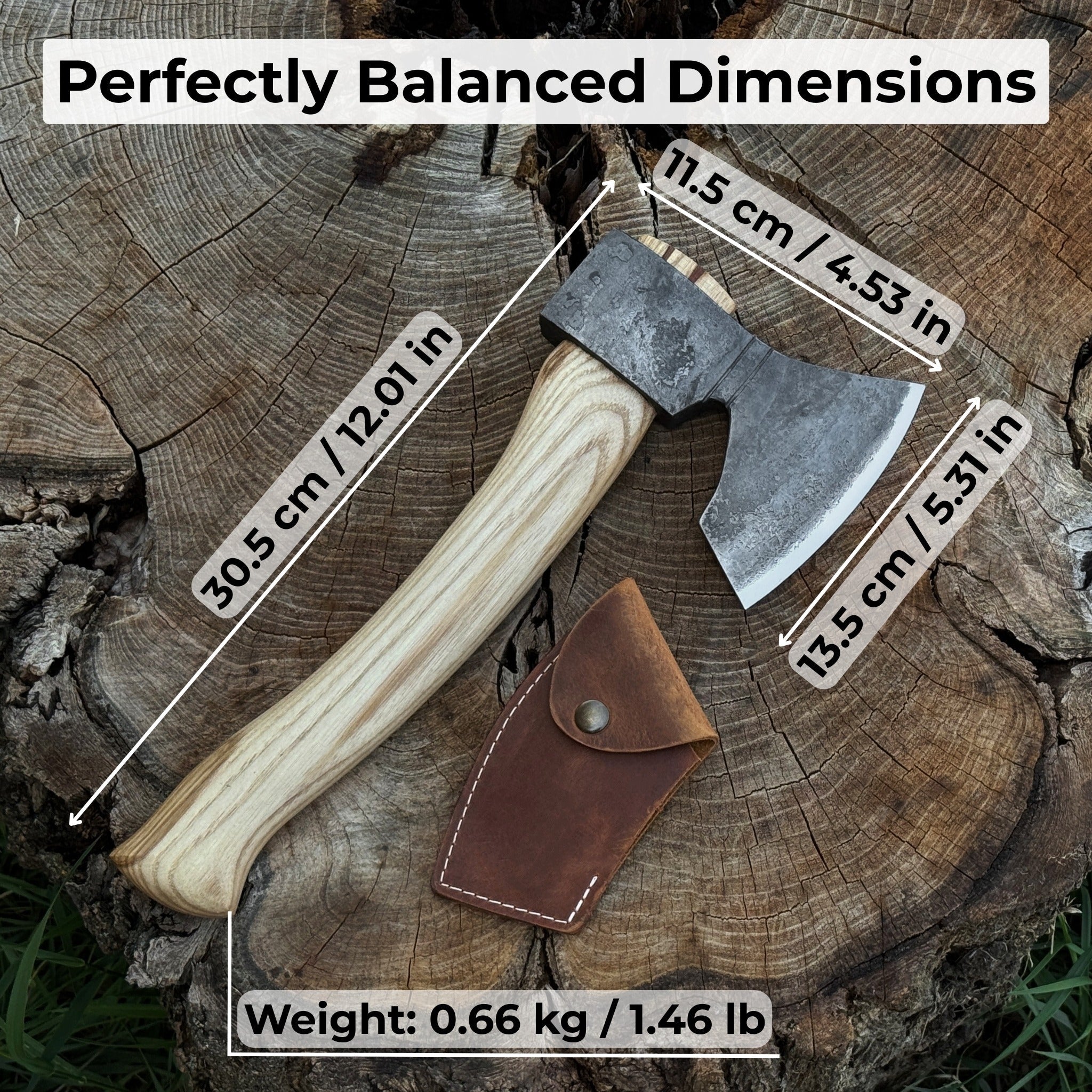

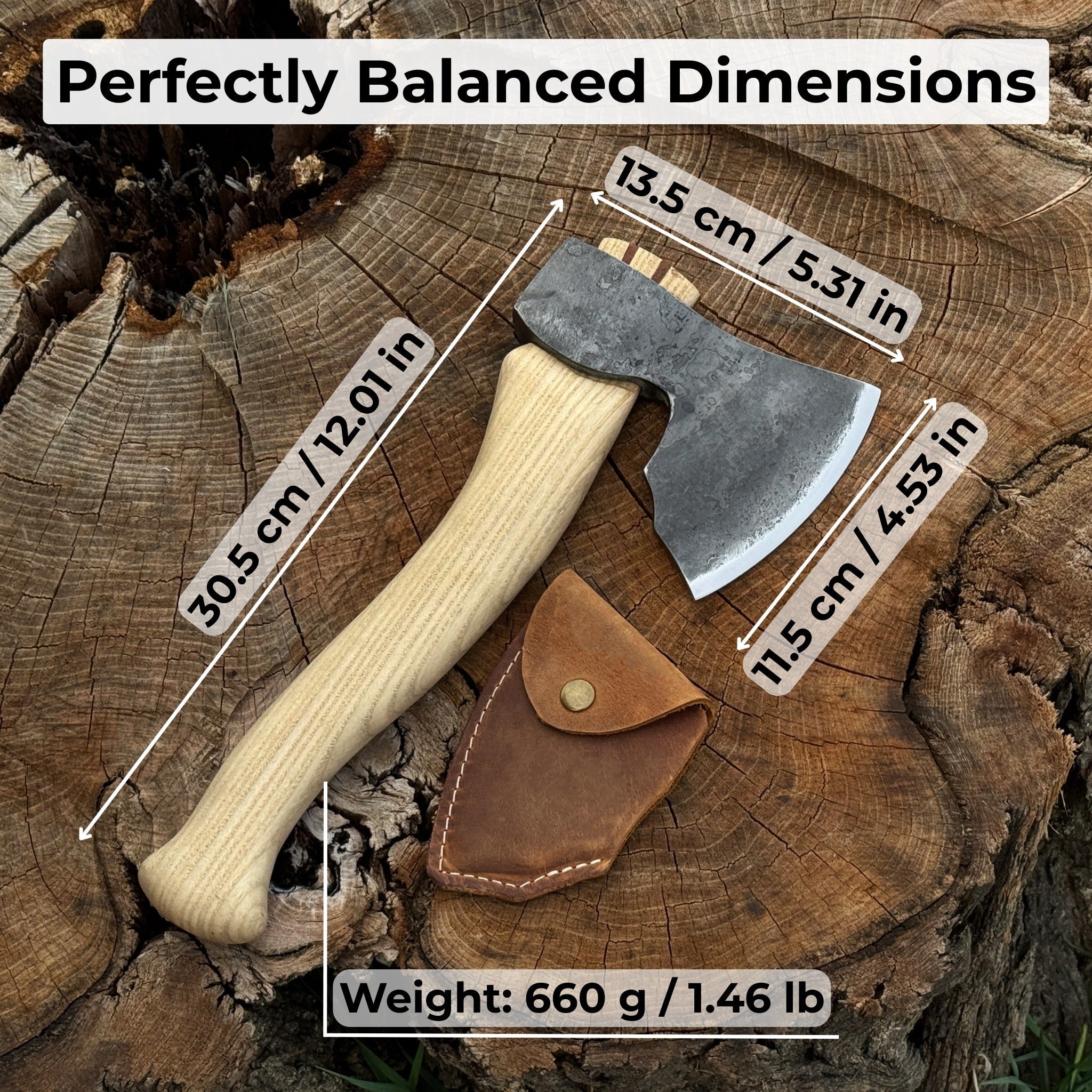

Small Carving Axe, 0.66 kg (1.46 lb)

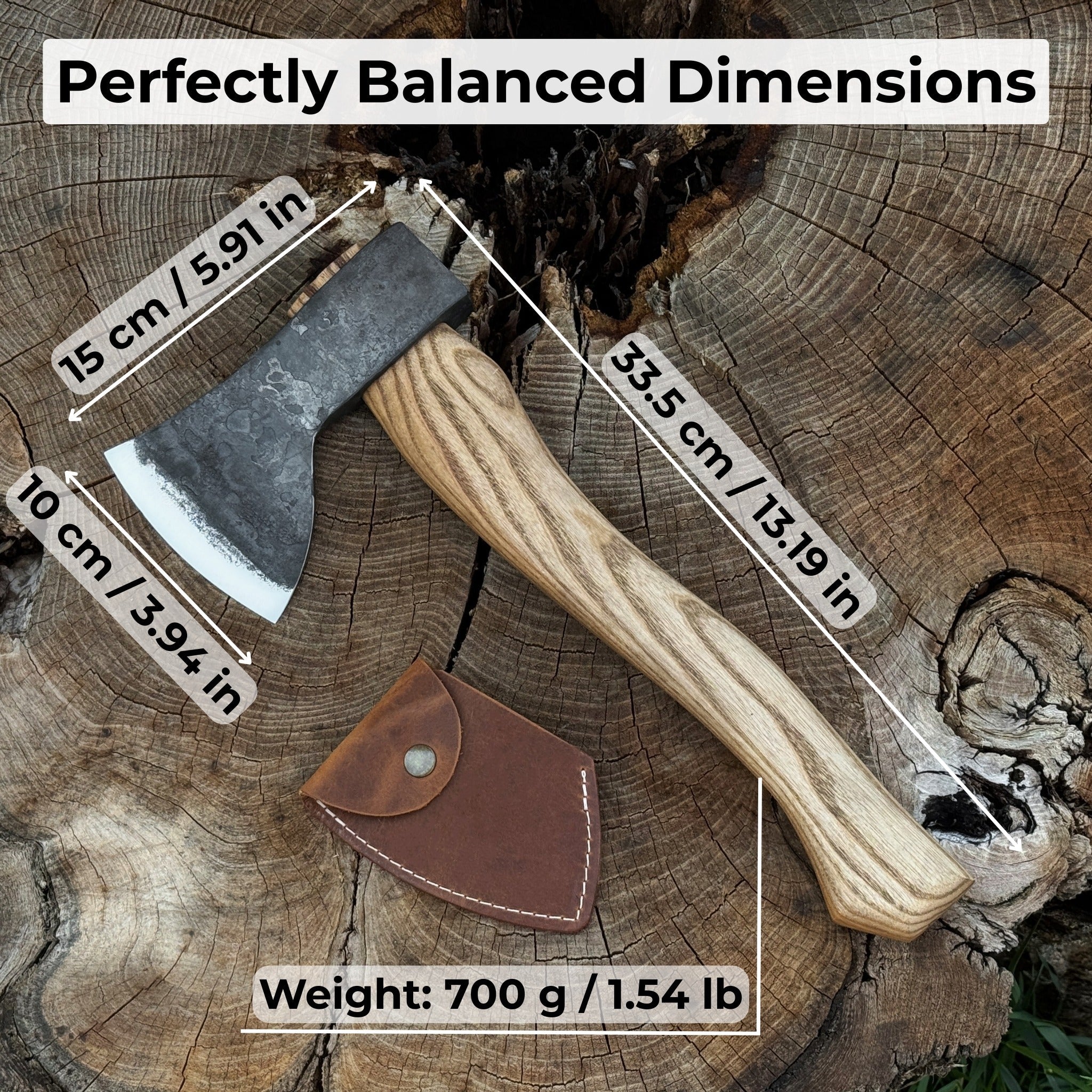

Small Carving Axe, 0.7 kg (1.54 lb)

Bushcraft Axe – Camping Hatchet 0.74 kg 1.63 lb

Small Carving Axe with Belt Loop, 0.47 kg (1 lb)

Introduction to Carving Axes

Carving axes can also be defined as single-handed woodworking hatchets that are smaller and lighter than traditional axes. The bevel of the blade can vary, with some woodworking hatchets having single bevels for better precision, and some having double bevels (sharpened on both sides), allowing for consistent cutting in any direction of the swing.

Choosing a double-beveled wood axe can be especially beneficial for beginner craftsmen, as it simplifies the learning process, enabling deeper and smoother cuts. Double bevels are also equally suitable for left- and right-handed carvers.

Carving axes are designed to handle versatile woodworking tasks, including felling, limbing, and splitting. And if you frequently perform these tasks, an axe with a 30-33 inch handle is highly recommended.

Woodworking axes are great for wood carving projects like carving spoons, bowls, and other similar items. The handle of a wood carving hatchet is usually curved, which makes it easier to slice delicately.

Depending on the task, a carver may grip the handle near the end for more powerful swings or closer to the axe head for better control and smoother transitions.

Types of Carving Axes

Carving axes are designed with specific features and purposes in mind. From the robust traditional wood carving axes to a specialized wooden hatchet, these tools vary in bevel type, blade shape, handle length, and axes tool weight. Depending on the type of carving you are doing, choose the tools that will do work for you with most precision and efficiency.

To better understand what types of woodworking axes you need, we have outlined a few broad categories.

Traditional Carving Axes

Traditional woodworking axes have different specifications, but most of them share these features:

- Head: Often have a broad, heavy head made of forged steel, making the tool suitable for chopping. Thin blades can make them also suitable for carving projects.

- Bevel: Bevel types may be single or double, which influences their cutting efficiency. Double bevel axes are preferred when you need to achieve more control over a carving. The edge geometry is more convex, making the wooden axe suitable for heavy use.

- Handle: Traditional shape is slightly curved and made of durable hardwoods to resist vibration and last longer. The handle length directly impacts the woodworking axe’s application. Longer handles will allow for more powerful swings, making them suitable for such tasks as splitting logs and felling trees. Shorter handles offer more flexibility and could be useful for detailed woodworking and carving.

- Weight: Typically heavier than their modern versions.

- Manufacturing techniques. Traditional tool is often a hand-forged hatchet. This manual process of forging allows for customization.

- Purpose: Designed for chopping, splitting, and felling trees. Can be a valuable part of your camping gear equipment. A good example is a chopping axe.

Traditional Swedish woodworking axes stand apart due to their high-quality steel and traditional forging methods. These tools usually have a thinner, more curved blade, allowing for more controllable cuts and a single-bevel edge (with right or left grind) to make cutting actions like skimming or flattening more efficient.

Modern Carving Axes

Unlike their traditional versions, modern axes are designed with contemporary materials that offer better durability and ergonomics. The weight of traditional axes is distributed so that a craver can amplify the force of the swing, making them good companions for your camping gear and larger projects.

- Head shape and weight. Modern woodworking axes tend to feature a thinner and longer blade, designed based on the intended use. The weight is usually light enough for doing detailed carving projects, preventing arm fatigue.

- Edge geometry. Geometry varies from convex to flat grind. Flat edges handle various woodworking tasks requiring detailed and accurate work. They are very easy to sharpen. Convex grinds are known for their durability and strong resistance to edge chipping and are a good choice for heavy use.

- Handle design. A lot of attention is given to creating ergonomic handles that fit well in the hand. The axes tool handle may feature curves or even textured grips. Modern carving axes often have shorter handles to ensure better mobility when working on smaller projects.

- Materials. While steel blade is typically used in the traditional wooden axe, a modern wood carving hatchet uses carbon steel (or high-carbon steel), which can be easily refined. Some tools use stainless steel, making the blade resistant to corrosion. Handles can be made of hardwoods, following classic design, or synthetic materials like polymer for weather resistance and durability.

- Manufacturing techniques. Modern axes are often manufactured through mechanized processes. This makes them uniform in shape, weight and balance. This allows for easier quality control.

- Purpose. Equally good for specialized tasks and camping. Many modern carvers prefer using modern axes with traditional woodworking techniques due to their comfort and efficiency. In this case, it’s just part of a multistep woodworking process, not a one-size-fits-all solution.

Specialized Carving Axes

Specialized carving axes serve different purposes. Depending on the project you plan to do, your axe choice should be made accordingly. The most common types are:

Spoon Carving Axe

Purpose. Designed for performing small woodworking projects like bowl or spoon carving.

Key features:

Lightweight. Given the detailed work required, this wood carving hatchet is much lighter than a general-purpose hatchet.

Curved edge. The curved blade helps perform such tasks as scooping and hollowing.

Short handle. The short size of the handle makes it easier to control and create intricate designs.

Single bevel. The single bevel creates more control over the carving process.

Broad Carving Axe

Purpose. A great choice for hewing logs or roughing out larger chunks of wood.

Key features:

Wide blade. A broad and flat blade is ideal for flattening large surfaces.

Single bevel on one side. This type of bevel allows for more precise cuts.

Offset handle. The handle can be offset to one side to keep hands away from the wood surface.

Felling Axe Adjusted for Carving

Purpose. Ideal for felling trees but can be adjusted for larger carving projects.

Key features:

Heavier head. The heavier weight helps remove large amounts of wood quickly.

Longer handle. Useful for larger carving projects, as it offers more leverage.

Double Bit Carving Axe

Purpose. Offers more versatility with two edges.

Key features:

Two blades. Typically, one side is for chopping, while the other is for green woodworking tasks.

Balanced weight. The weight is balanced between the two blades.

Heavy head. May require additional control during your work on smaller projects.

Features to Look for in Carving Axes

To ensure you get the best wood axe for your needs, here are some features to consider:

Blade Material and Sharpness

First off, the blade shape should match the type of work you plan to do. A curved blade is ideal for green woodworking, while a straight or slightly rounded blade is perfect for general-purpose carving.

If you are a fan of traditional woodworking techniques, choose a wider blade. For smaller projects, choose a wood axe with a narrower blade.

Blade material is another important consideration. High-carbon steel holds a sharp edge longer, while stainless steel is more rust-resistant but doesn’t hold edge as well as high-carbon steel.

Additionally, check if the wood axe has been properly heat treated. This is crucial for maintaining the needed level of hardness (HRC 56-60).

Weight and Balance

The recommended head weight for a lighter wooden axe is between 1-1.5 pounds, while for a heavier head the ideal weight should be around 2-3 pounds.

Balance is something you can evaluate only when holding the wood axe in your hand. Proper weight distribution prevents quick fatigue and helps work for long hours.

Durability and Maintenance

The durability of a wooden hatchet and axe depends on several factors. Carbon steel ensures a longer blade life, and properly heat-treated steel is less likely to chip or lose the edge.

The handle should be made of hardwoods or synthetic materials like fiberglass for better weather resistance.

Secure head attachment, strengthened with epoxy or resin, may help reinforce the head.

Regular sharpening, protective covers, and proper maintenance (cleaning, handle and blade care, dry storage) can extend the lifespan of the wooden hatchet.

Choosing the Right Carving Ax for Your Needs

When choosing the right carving axe for yourself, consider your proficiency level. As a beginner, select a wooden hatchet that is easy to use, safe, and multipurpose. Some features to think of first:

- Weight: It should be light enough (1-1.5 pounds) to help you control the tool easily and perform different cravings without the risk of accidental slipping.

- Handle design: Look for an ergonomic design that ensures better grip and comfort. The recommended handle length is around 14 inches.

- Blade shape and edge: The blade material like carbon or high-carbon steel is preferred for its ease of maintenance and ability to retain a sharp edge longer.

For professionals, a wood axe that offers specialization, high durability, and precision is important. Some key features to look for:

- Tailored weight. This can vary depending on the task. For heavy use, a 1.5-2 pounds axe may be best; for smaller carvings and precision work, lighter axes are preferred. Some manufacturers offer customization, allowing professional carvers to order woodworking axes balanced to their style of carving.

- Custom handles. Professionals may prefer handles made of premium woods or composite materials.

- Specialized blades. Professionals may choose to have a collection of carving axes that feature different blade shapes: straight, single or double bevel, and curved.

- Sharpness. Holding an edge exceptionally well is extremely important, so a professional is likely to choose high-steel that can be sharpened to a razor’s edge for precise work.

How to Use a Carving Ax Safely

Maintaining proper level of safety while using a carving axe involves regular practice and adherence to basic safety rules.

Proper Grip and Technique

Two-handed grip: Allows for more control when you place your non-dominant hand close to the wooden axe head and a dominant hand near the handle base.

Grip for controlled cuts: Put your dominant hand closer to the axe head to prevent accidental overcutting.

Practice using different techniques to gain confidence in your carving skills:

Controlled swings: Make controlled swings rather than forceful ones to avoid injuries.

Maintaining proper angle: Practice making small angle cuts (10-15 degrees) to ensure more smoothness and avoid uncontrolled cuts deep into the wood.

Wrist action: Involve wrist during the cutting to evenly distribute the strength you apply across your arm.

Safety Gear and Precautions

Basic safety gear includes protective gloves and goggles to safeguard your hands and eyes from injuries.

Ensure your workspace is stable to prevent your workpiece from moving. Try using clamps for that.

Before starting your carving project, check the condition of your wood axe. Fix or replace loose heads or cracked handles.

Finally, keep your work area clean and your first aid kit handy in case of an accident.

Common Mistakes to Avoid

Overestimating your skills or using wrong carving techniques, such as a one-handed grip instead of a two-handed grip, can lead to serious injuries. Avoid cutting toward yourself or using a more pronounced angle while carving with a wooden axe, as the tool may get stuck, leading to uncontrolled movements.

An unstable workpiece and a cluttered workplace are also among common mistakes. Keep your workplace clean and your workpiece stable to stay safe.

Neglecting regular tool maintenance can compromise the longevity of the tool and your safety. A dull blade requires more force to cut and increases the likelihood of slips.

Conclusion and Final Tips

Summing up, choosing the right woodworking carving axe guarantees great satisfaction with your final work and directly influences your safety. Understanding the different types of wooden axes and their intended uses will help you progress as a professional.

And some final tips:

- If you are new to the world of woodworking, start with a light, multipurpose axe.

- Prioritize safety gear and stable position of the workpiece.

- Develop a habit of regularly checking the axe condition.