Set of 5 Universal Ash Wood Handles

Set of 5 Compact Ash Wood Handles

Set of 5 Ash Wood Replacement Handles

5-Piece Ash Handle Set with Rings

Set of 5 Ash Wood Knife Handles

Why Choose Wooden Handles for Tools

There is a reason carvers and craftsmen have relied on wood tool handles for generations. A well‑made wood handle does more than connect you to the blade or chisel—it shapes the way the tool feels, performs, and lasts.

Benefits of wood handles compared to metal or plastic ones

Instead of focusing only on durability, carvers often choose a wood handle for the comfort and tradition it brings to their work and tools set. Beyond that, the advantages of wooden handles over plastic or metal include:

- Absorbing shock: Natural wood reduces vibration and impact.

- Temperature comfort: Wood stays warmer in cold weather and does not cling to the skin.

- Ease of repair: A broken handle can be repaired or replaced with relative ease. Carvers also appreciate how simple it is to shape wood for a grip that feels personal and ergonomic, especially when working with a wood carving kit.

- Grip and feel of a wood handle: Many wood carvers prefer the secure hold wood offers, often more reliable than smooth plastics or polished metals.

- Weight distribution: In tools like a knife, wood is often lighter than metal, allowing more of the weight to sit in the head of the tool, which improves efficiency.

How a properly shaped wooden handle improves precision and safety during work

Ergonomic shaping, the right size, and the natural qualities of a wood handle give carvers a grip that feels secure and comfortable. Precision depends on steady control, and well‑designed tool handles make this possible. Shaped to fit the hand, they provide stability for fine cuts or steady strikes.

Balanced design improves weight distribution, reducing wrist strain and allowing force to be applied more accurately. Unlike most of the metal handles, wood handles for tools absorb vibration better and give clearer feedback from the cutting edge or striking surface.

Properly sized handles prevent slipping or cramping, keeping carvers in control with their carving tools. A smooth finish avoids splinters and blisters, and wood’s natural texture maintains traction even when hands are damp.

Main Types of Wooden Tool Handles

Wooden handles for tools come in many forms, from contoured designs to straight, universal styles. For easier maintenance, some wood handle tools are made with replacement options, which is especially useful for carvers who spend long hours at work or simply want to replace a worn handle quickly when the time comes.

Universal Wooden Handles for Tools

Universal wooden handles are often included in a full carving tools set, though they may vary slightly depending on the blade or chisel type. While not always identical across every tool, they share a consistent design that makes them interchangeable. Carvers highlight several benefits:

- Versatility: A single wooden handle style can fit multiple carving knives or chisels, making it practical for a carving knife set.

- Balance and weight: Typically light to medium weight (around 40–60 grams), offering good control without tiring the hand.

- Comfort: Ash wood handles are praised for shock absorption and a warm, natural feel.

Example: Set of 5 Universal Ash Wood Handles – designed to fit a range of carving knives, offering balanced weight.

Compact and Replacement Wood Handles

Compact wooden tool handles are often used for chisels and micro‑carving tools, where precision matters more than leverage. Replacement handles are valued for extending tool life, especially for knives and drawknives. Some of the popular characteristics include:

- Compact handles: Shorter length, lighter weight, ideal for detail work and fine cuts.

- Replacement handles: Made for chisels, gouges, knives, and drawknives; usually shaped for ergonomic grip and reinforced with rings (brass or aluminum) for durability.

- Practicality: Easy to swap when a wooden tool handle breaks, saving cost and keeping tools functional.

Examples:

- Set of 5 Compact Ash Wood Handles – smaller size for precision carving.

Wooden Knife Handles

Knife handles are a frequent topic in carving communities. Carvers emphasize that the type of wooden tool handles affects grip, safety, and fatigue:

- Straight handles: Simple, traditional, easy to control for general carving.

- Contoured handles: Ergonomic shaping for comfort during long sessions.

- Tapered handles: Better for fine detail work, offering precise control.

- Convenience: Contoured styles are often preferred for long carving sessions, while straight handles are lighter and easier to replace.

Example: Set of 5 Ash Wood Knife Handles – designed specifically for carving knives, including detailed carving knives, offering a secure grip and balanced feel.

Ash Wood Handles – A Professional Standard

A well‑balanced and durable wood handle adds greatly to the workability of a knife set or other woodworking tools. Some of the most popular options are ash, oak, and walnut—and here’s why.

Why ash is the most balanced material for tool handles

Hickory is often favored for its shock absorption in heavy-duty tools, but ash has its own strengths. It offers a great mix of durability, affordability, and ease of shaping, the qualities that make it a classic option for a wooden handle. Carvers often highlight a few key benefits of ash:

- Strong and reliable, often ranked alongside hickory as one of the toughest choices.

- Attractive grain that adds a traditional look to wooden handles for tools.

- The natural grip and comfortable feel make it easy to hold during extended work with a chip carving kit.

- Cost-effective without sacrificing performance.

Best types of wood for knife handles: ash, walnut, oak

The choice of the wood for knife handles is about finding the right balance between looks, weight, and toughness.

Walnut is often praised for Japanese-style wa handles: It is simple, elegant, and affordable. Its lighter density keeps blades balanced, preventing them from feeling too heavy in the handle.

Oak, on the other hand, is a traditional European hardwood known for toughness and flexibility, though it can be softer and more prone to marks.

Ash may not be the first choice for kitchen knives, but its strength and resilience make it excellent for outdoor and utility blades. From a hunting knife to a swiss knife, ash delivers a good grip and durability that hold up under demanding use.

How to Choose the Right Wooden Handle

For woodcarving tools, carvers generally prefer hardwood handles because they are denser and stronger than softwoods. Hickory, ash, and oak are longtime favorites. It is also important to consider handle length, grip, and balance. Let’s take a closer look.

Matching handle diameter and length to your tool

Matching the diameter and length of the wood handle to the tool depends on the task and the level of precision required for your whittling wood carving project.

Diameter: Grip and Power

- Large diameter (mallet tools): Best for medium to large carvings. A fuller shape rests in the palm, adds leverage, and reduces fatigue.

- Small diameter (palm tools): Ideal for fine detail work. Compact size gives better control.

- Ergonomics: Octagonal wooden handles improve grip and prevent rolling compared to round ones.

Length: Scale and Control

- Short handles: Perfect for small knives and gouges where precision matters most.

- Long handles: Suited for bigger carvings and deeper cuts, giving room for two‑handed pushing or mallet strikes.

Oil, Wax, or Lacquer – Which Finish Is Better?

Oils and waxes are often preferred for tool handles because they soak into the wood, adding comfort and durability. Drying oils, such as boiled linseed or Danish oil, are very popular for woodworking tools, as they cure to a hard, non‑slippery finish that is easy to maintain. These oils make the wood for knife handles really strong and are easy to refresh with light sanding and reapplication. Hard coatings like lacquer or varnish are usually avoided, as they are less comfortable to hold and are prone to chipping.

How surface treatment affects protection and appearance

Surface treatments can make a big difference in how wooden handles for tools perform and look. Regular finishing helps protect the wood from moisture and wear, keeps the grip comfortable, and brings out the natural beauty of the grain. Applying oils or waxes from time to time also prevents cracking and extends the lifespan of the wooden handle.

Pros and cons of different coatings

Drying oils, such as boiled linseed or tung oil, are often chosen for outdoor and woodworking tools because they penetrate the wood deeply, adding strength, water resistance, and a comfortable grip. Their main drawback is the long curing time and the need for occasional re‑oiling.

Non‑drying oils and waxes, like mineral oil with beeswax, are common for kitchen knives and utensils where food safety matters. They keep the wood conditioned and give a soft sheen, but they need frequent reapplication.

Hard coatings, including lacquer or varnish, are usually reserved for decorative or custom pieces since they provide a glossy shell and strong sealing, but they can chip or crack over time, and once damaged, they are difficult to repair without stripping the entire finish.

So, for a wooden tool handle that sees heavy use, oils and waxes are usually the most practical choice.

How a Polished Surface Affects Grip and Comfort

A polished surface can look impressive, but it changes how a wooden handle feels in use. Glossy coatings often reduce tactile feedback, making the grip less secure. In contrast, oil‑treated or waxed finishes cure to a natural, non‑slippery texture that feels much more comfortable. For carvers working with whittling wood, most prefer finishes that balance protection with a pleasant, secure grip rather than shine.

Handle Sets for Craftsmen and Enthusiasts

If you feel it is the right time to choose a set of long‑lasting wooden handles, we have you covered. At Forged Steel Tools, we craft tools along with sets of replacement handles. See some of the options below and explore more on this page.

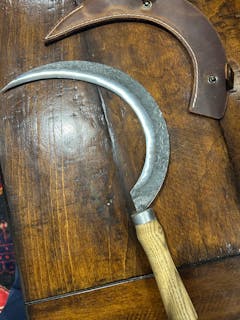

Set of 5 Ash Wood Knife Handles

Slim 12cm ash wood handles, lightweight and curved for precision. No reinforcement. Best suited for carving knives, whittling knives, and small utility blades.

Set of 5 Ash Wood Replacement Handles with Aluminum Rings

Durable 9.5 cm tapered tool handles with aluminum rings for added strength. Ideal for chisels, knives, and gouges under heavy use.

Set of 5 Ash Wood Replacement Handles for Chisels and Gouges

Rounded 12.5 cm ash handles reinforced with rings, built for mallet striking. Perfect for bench chisels and carving gouges.

Palm Grip Handles for Wood Carving Tools (Set of 5), 6 cm (2.36 in)

Compact 6 cm palm‑grip wood handles, lightweight and ring‑reinforced. Designed for small chisels and fine detail carving tools.

5-Piece Ash Wood Handle Set for Knives, Chisels, Drawknives, and Carving Tools

Versatile 13 cm ash handles with rings and linseed oil finish. Suitable for knives, chisels, drawknives, and general carving tools.