Hand-Forged Double Blacksmith's Hammer, 1 kg (2.2 lbs)

Hand-Forged Double Blacksmith's Hammer, 1.5 kg (3.3 lbs)

What is a Hammer for Woodworking and Leathercraft?

Purpose and Role of Specialized Hammers

A hammer is a partner in precision and a force for transformation. Its versatility today is unmatched. The design, weight, and material are carefully crafted to suit the specific demands of each task and material.

In leatherworking, where every cut and cease requires a delicate touch, specialized hammers like mallets or mauls feature softer heads to help drive punches, shape leather, set rivets, and smooth edges without leaving a mark.

In woodworking, on the other hand, hammers have sturdy construction and a well-balanced weight to drive chisels, assemble joints, break down the materials, and texture and shape wood. A dead-blow hammer is one of the woodworking hammers examples designed to reduce damage to the struck area and offer better control of the stroke’s power, thanks to its rubber head, making it useful for assembling large carcasses.

Differences from General-Purpose Hammers

A general-purpose hammer handles a great variety of tasks, primarily in carpentry, construction, light demolition, and general household tasks. They usually have metal heads for strength, with flat striking faces and handles made from wood, fiberglass, or metal. They come in different types and the most common include:

- Claw Hammer or Curved Claw Hammer: Features a flat striking face for driving nails and a curved claw on the opposite side to remove nails without damaging the wood surface. It is also widely used for household repairs.

- Ball Pein Hammer: With a rounded ball end opposite the flat striking face, this hammer is usually used in metalworking for peening and shaping metal, driving punches, and assembling joints.

- Club Hammer: Also known as a lump hammer, it has a short handle and a heavy, double-faced head with flat striking surfaces on both ends. It is used for breaking up concrete, driving stakes or large nails, and shaping metal or stone.

In contrast, specialized hammers tools often use softer materials like rawhide, rubber, or wood that prevent damage to the workpiece. These tools are designed for precision and control, often lighter and better balanced for long leathercraft and woodworking sessions.

Unique Design Features of Our Hammers

Shape and Size for Different Crafting Needs

At Sharky Forged Steel Tools™, we specialize in crafting handmade tools from high-grade 52100 carbon steel (the ASTM A295 standard) for better durability and efficiency. The ergonomic ash wood handles allow for extended work sessions without discomfort.

Our hammers arrive ready to use, so no prep is required before getting to work. The range of hammers includes:

- Rounding Hammer: Weighing 490 grams (17.3 oz), this leather hammer is perfect for precision tasks, e.g. setting rivets, punching holes, and shaping leather. The steel head provides controlled strikes, suitable for both leatherworking and light metalwork. This hammer can also be used for wood hammers’ tasks like setting dowels or light assembly work.

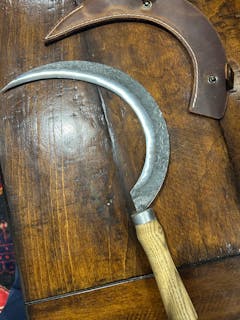

- Curved Claw Hammer: This 0.5 kg (17.6 oz) hammer with wooden handle is ideal for general use and comes with a leather holster for tool belts. The forged and heat-treated head ensures durability, while the claw is suited for pulling nails and light prying tasks.

- Small Brass Hammer: Weighing 400 g (14.1 oz), this high-quality brass tool is non-sparking and safe for use in environments with flammable materials.

- Double Blacksmith’s Hammer: At 1 kg (2.2 lbs), this hammer excels in heavy-duty forging tasks. It is designed to pull steel effectively at various angles, offering versatility for shaping and stretching metal.

- Leather Hammer: Available in weights from 150 to 190 grams, this wood handle hammer is excellent for delicate leatherwork, ensuring precise strikes. Ideal for both hobbyists and professionals.

Precision of the Hammer Head

The hand-forging process applied by Sharky Forged Steel Tools™ enhances the precision of the hammer head through multiple manufacturing steps.

Hand-forging allows for better control in shaping the steel. Craftsmen continuously check and adjust the form, improving dimensions, balance and symmetry of the hammers’ heads. This results in refined striking surface and optimized weight distribution, ensuring that the hammer delivers optimal force during use.

During the hardening and tempering stages, the hammer head undergoes further heat treatment to enhance its strength and long-lasting performance. After forging, the hammer head is finished by hand to achieve smooth edges and a precise striking surface, enhancing the overall durability of the tool.

For more information on our process or customizing leather or wood hammers, contact us for expert advice.

Key Applications for Hammers in Woodworking & Leathercraft

Precision Work in Woodcarving

Beyond traditional uses like driving nails or prying apart materials, woodworking hammers offer control and precision in striking chisels. These hammers are also essential for assembling joints and aligning wood pieces during furniture construction.

Here are the key uses:

- Assembling Joints: Wood hammers, particularly dead blow mallets, are used to tap joints into place without damaging the wood.

- Chopping Mortises: For tasks like carving mortises in hardwood, a heavy lump hammer is essential for removing waste material and creating deep joints.

- Setting Dowels of Pins: A brass hammer is ideal for delicate tasks like inserting dowels, as its soft face prevents damage to delicate surfaces while ensuring a secure fit.

- Fine Woodworking: When crafting delicate furniture pieces, a cross pein hammer ensures that small nails or brads are driven with precision, preventing the wood from splitting.

- Flattening Metal Components: A ball pein hammer is used for flattening metal elements in woodworking projects.

Shaping and Forming Leather

Leatherworkers often have a variety of hammers on hand to handle different types of work. Let’s explore their main applications:

- Hammering Leather: The rib side of a dual-sided craft hammer is used to hammer leather down and keep it rounded.

- Setting Rivets: A ball peen hammer's flat face can be used for striking and setting rivets.

- Tooling Leather: Mallets, such as the yellow mallet, can be used for tooling leather.

- Striking Leather: Tapered mauls offer controlled pressure due to their widening heads.

Choosing the Right Hammer for Your Craft

Matching Hammer Types to Specific Projects

The choice of hammers tools depends on the specific task and the desired outcome a craftsman wants to achieve. Properly matching the tool to the job ensures the right level of force and precision, contributing to successful project completion.

Consider these factors when selecting woodworking hammers or hammers for leatherwork:

- Determine the Task: Identify whether you need a wood hammer for framing, finishing, or delicate joinery. For leathercraft, decide if you need a mallet for stamping and tooling or a hammer for shaping and smoothing.

- Select a Comfortable Grip: Choose an ergonomic handle that feels comfortable in your hand. Handle materials range from wood to metal, each offering different levels of comfort and shock absorption.

- Weight and Balance: Opt for a hammer that matches your strength and provides good control. Heavier hammers allow for more powerful strikes but can be more tiring, while lighter hammers are more suited for delicate work.

- Specialty Hammers: If you frequently work on specific types of woodworking or leatherworking projects, invest in specialty hammers to expand your collection as you build skill.

Common Mistakes When Using Hammers in Craftsmanship

When it comes to hammer techniques, everything seems to be straightforward. However, there is a number of common mistakes that can affect the quality of work and safety:

- Using the Wrong Type of Hammer: Applying a heavy-duty hammer to a delicate material risks damaging the workpiece and spoiling the project. Always select the hammer based on the task and material.

- Incorrect Swing, Grip, and Body Position: Take regular breaks and maintain a stable stance. Holding the hammer too tightly or loosely can cause hand strain or reduce control. Aim for a firm grip, and use your wrist and elbow to swing.

- Ignoring Safety Measures: Protect your eyes from debris by wearing safety glasses, and use gloves to prevent injury.

- Inadequate Maintenance: Regularly inspect the hammer for signs of wear. Use fine-grit sandpaper to remove rust, avoid making the handle slippery with oil, and sharpen pointed hammers with a metal file.

Conclusion

Unlike general-purpose hammers, which are versatile but less specialized, specialty hammers use materials like rawhide, rubber, or wood to ensure precision and prevent damage of the workpiece.

Sharky Forged Steel Tools™ offers a range of high-quality, ergonomic hammers tailored for both woodworking and leathercraft, ensuring durability and comfort for extended use. For recommendations on which hammer to choose, contact us right away!