4-Piece Spoon Carving Tool Set with Leather Roll

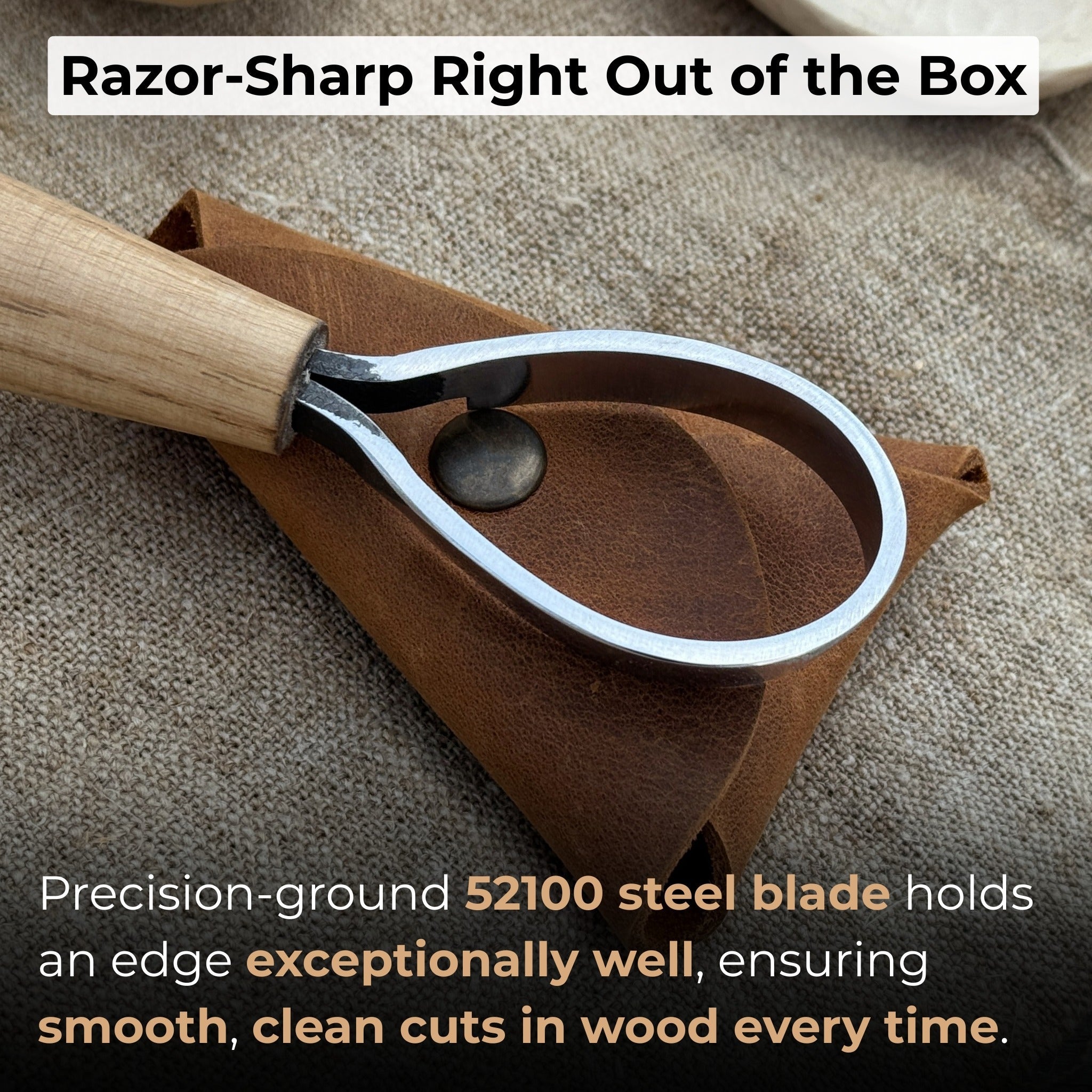

Spoon Carving Scorp Knife, ⌀3.5 cm (1.4 inches)

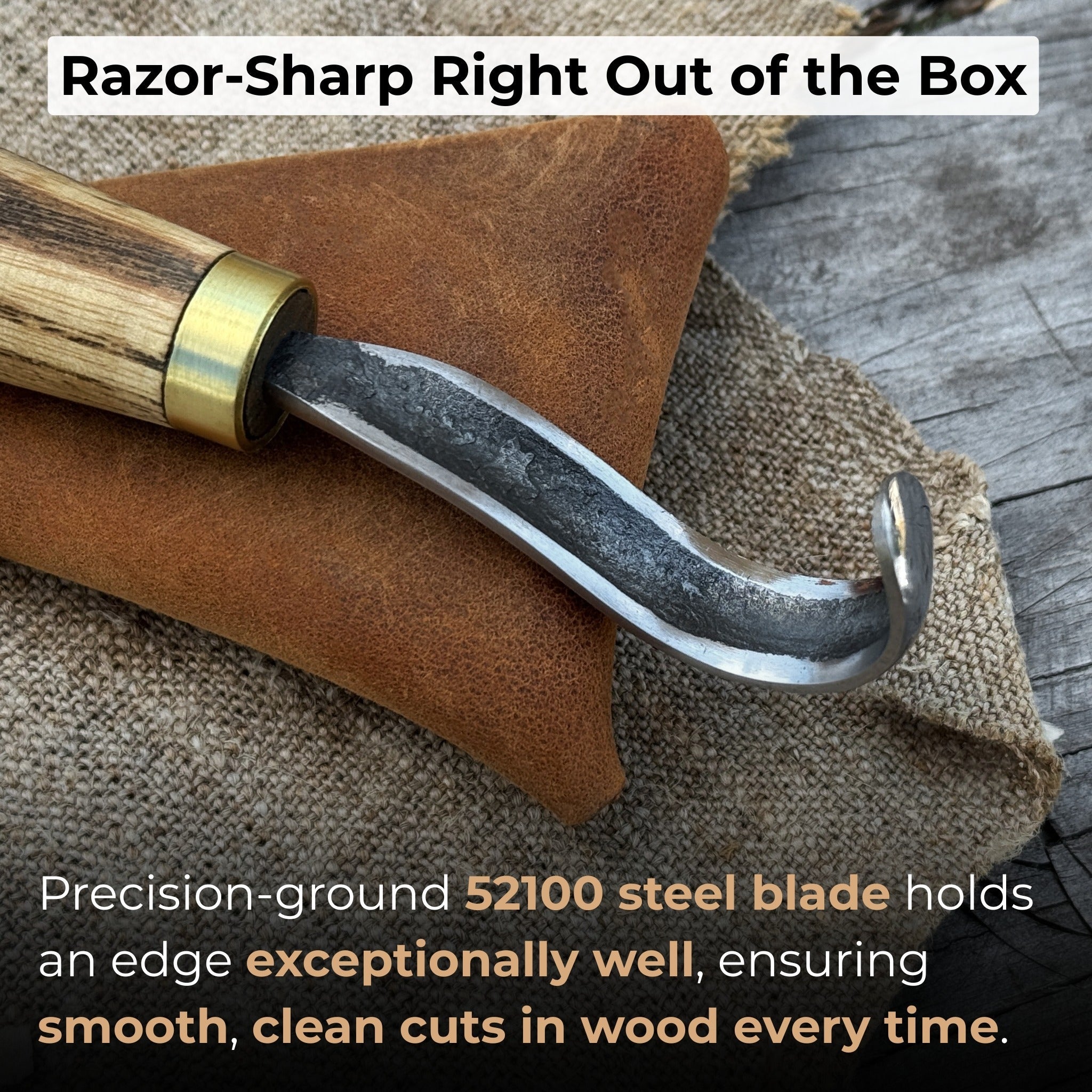

Spoon Carving Hook Knife – Long Curved Blade 7 cm (2.7 inches)

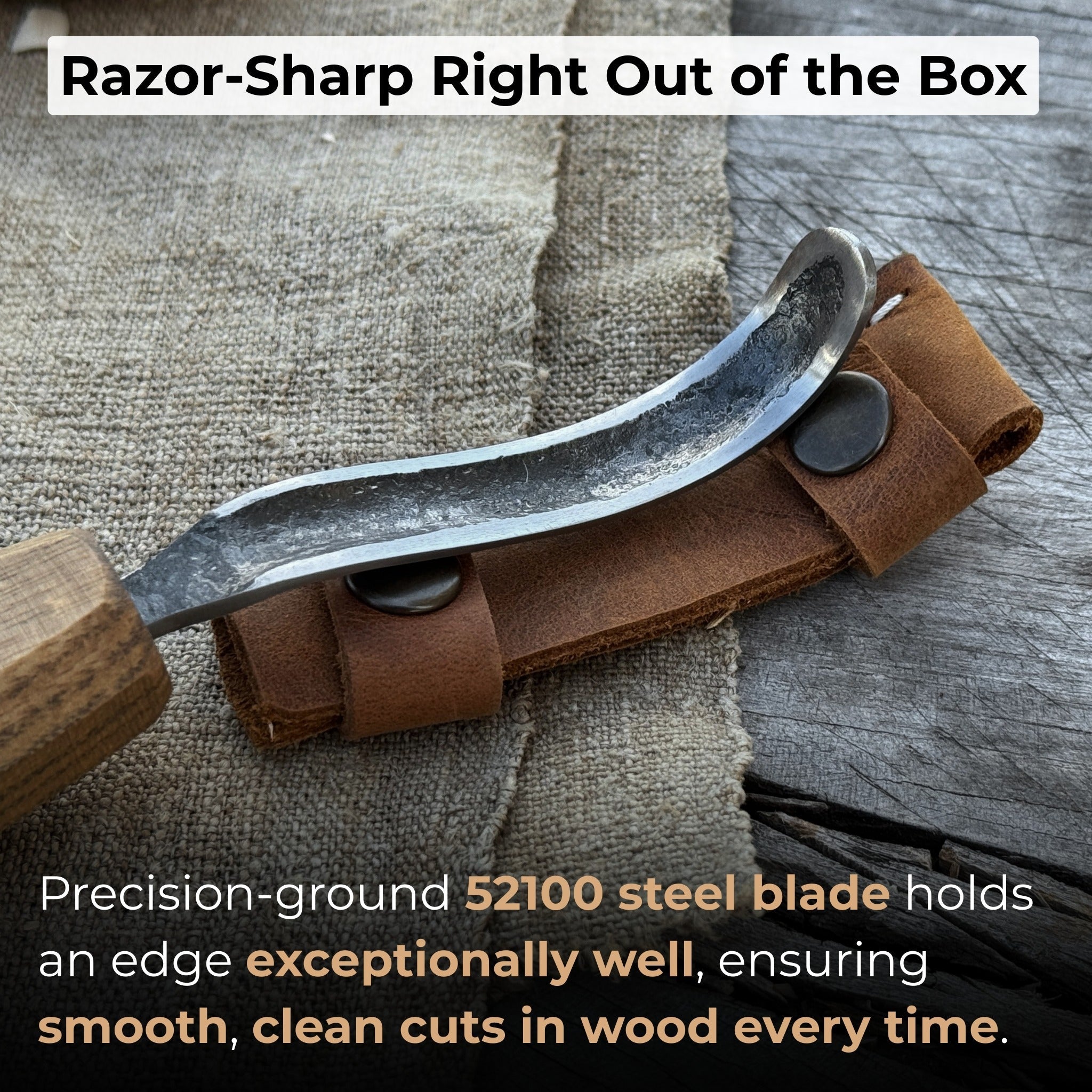

Spoon Carving Hook Knife, ⌀3 cm (1.2 inches) with Leather Case

Spoon Carving Scorp (Round) Knife, ⌀3 cm (1.2 inches) with Leather Case

Spoon Carving Hook Knife with Leather Sheath, Blade 3.5 cm (1.38 inches)

3-Piece Spoon Carving Tool Set with Sharpening Board

Small Spoon Carving Hook Knife with Octagonal Handle, 6 cm (2.36 inches)

Spoon Carving Hook Knife – Large Radius Curve 5.5 cm (2.17 inches)

Spoon Carving Hook Knife, ⌀ 4.5 cm (1.77 inches)

Spoon Carving Tools: Essentials for Every Woodworker

Whether you are a seasoned woodworker or someone who enjoys the hobby on weekends, choosing the right spoon carving tools can make a big difference to your woodworking projects.

If you have researched the market, you may have come across carving kits and individual tools of different types and shapes. The question remains: how do you choose the best spoon carving knife out of so many offered, what types of the tools can help achieve better precision, and how one should maintain a carving set. Let’s dig in.

History and Tradition of Spoon Carving

The tradition of carving spoons appeared as early as ancient people discovered the need to have efficient scooping tools to consume liquids and food. Historians say that they were first invented in Ancient Egypt. They featured religious symbols and hieroglyphics and were owned by Pharaohs.

The craft evolved significantly in Scandinavia. The Vikings ‘tattooed’ wooden spoons with the tip of a knife, splitting wood fibers and then applying a pigment to the cuts to highlight the drawing. This carving technique was called ‘kolrosing’.

In the 16th century, Apostle Spoons, featuring an image of a saint on the handle, became popular as christening gifts. In the 17th century, the tradition of carving lovespoons emerged in Wales. And the history continued.

Those traditions, in turn, influenced the environment that shaped modern craftsmen, helping in the development of carving techniques and the enhancement of today’s carving spoons tools.

Types of Spoon Carving Knives

It has always been the subject of hot debates as to which spoon knives are better for carving. However, the basic wood carving kit would definitely include an ax, a straight knife, and a hook or a sloyd knife.

- Axes

When it comes to axes, a carving ax will serve you a lot better than a wood splitting ax. It is sharper and requires less effort to carve wood. More characteristics would include:

Head: If you plan to carve spoons, a symmetrical grind with identical bevels on both sides might be more suitable. However, if you are right-handed and intend to use the spoon carving jig for some spoon carving and larger projects, search for a right-hand grind. If you are left-handed, choose a left-hand grind instead.

Blade: The blade should be made of a premium steel like carbon or stainless steel to ensure durability of the carving spoon tool.

Weight: Weight is an important consideration, as carving axes are single-handed tools (hatchets) and if they are light enough, you won’t get tired quickly or release the ax unintentionally. For most people the optimal weight would be 500-700 g.

Handle: To carve objects with curved surfaces, a 30-33 inch handle ax is highly recommended. It also excels at shaping flat surfaces. Another good option would be an ax with a 14 inch handle. It would be lighter in weight and best for light carving work like spoon carving, as it gives more control when working on smaller details.

Hatchet shape: The ideal hatchet for carving spoons features an extended blade for better slicing and a cut-out behind the blade to let you position your fingers behind the ax head for precise control.

- Straight Knives

Straight knives are essential for doing a lot of carving work, from roughing to fine detail work. A good wood carving spoon knife like that would have a wide, slicing bevel. Avoid choosing straight knives with tight curves and short blades. They create a feeling of inaccuracy and require extra sandpaper work.

- Hook Knives

Hook knives are used to carve out hollow areas. They are available in right and left-handed versions. While experienced carvers tend to use both, most beginners may find a single knife for their dominant hand sufficient. The knife blade should be thick enough to prevent flexing and vibrating. The handles should be comfortable to hold and make cuts, the recommended length could be 6-8 inches long.

- Sloyd Knives

Beveled on both sides, the sloyd knife can handle a variety of wood carving tasks, including whittling and carving. Its handle should feature multiple control points so that you can hold it comfortably in various positions. Look for the spoon knives with blades made from high-carbon or stainless steel and a polished and rounded back.

Using Spoon Carving Knives

Carving techniques may vary depending on the carver’s skill set and wood spoon carving tools available. Here are some of the most commonly used:

Wood Selection

Green wood is usually preferred over seasoned wood because it is easier to carve, it doesn’t dull your spoon knives fast, and it often has interesting curves that can be used to create unique, non-linear handmade spoon shapes. In green woodworking, the wood is split (not sawn) along the line of the fibers and carved across the grain, not along the grain.

Now, what types of wood are recommended as more durable and easy-to-carve? Some of the best ones are: birch, alder, applewood, and cherry. They are known for their fine grain; they carve well and are less likely to crack. Ring porous species of wood are not recommended as they are hard to carve. Pine and spruce contain a lot of resin, making the wood sticky and due to their open grain structure, they are more prone to splintering.

A piece of wood should be wide enough, so that you can split it into two parts and remove the pith. The recommended diameter could be 8-9 inches or wider.

Roughing Out

This involves removing big chunks of wood with an ax. The more axes work, the less the knives work.

Modelling

After roughing it out, use straight and sloyd spoon knives to refine the shape of the handmade spoon with a focus on the handle and a bowl.

Hollowing

The next step is carving out the bowl of the spoon, which is usually done with a hook knife.

Detailing

Here’s when fine details and smooth transitions are added. You can use smaller knives or chisels for that.

Finishing

When the outer shape is ready, wooden spoons are dried. You can now sand spoons if needed and then apply a finish like natural oils.

Wood Carving Safety Tips

Before you start a project, it is paramount to think of your safety. Learn some basic cuts to always carve away from your body and know how to grasp the knife properly.

Think of personal protective equipment you may need: safety gloves, finger guards, goggles, and dust masks.

Remember to keep your wooden spoon carving tools sharp at all times, as dull tools would require more physical effort and increase the risk of slipping and causing injury. Also, have a first aid kit handy for quick treatment.

Spoon Carving Knife Care

Taking good care of your spoon carving knives is as important as selecting the right knives set. This will increase tools’ durability and precision. Here are some of the most important things to do regularly:

Sharpening

The trials and errors of woodworking proved that maintaining control of the tool while sharpening is far more important than pressure. Recommended angle is roughly a 20 degrees angle. For a carving ax, an ax bevel should be sharpened to about 18 degrees for the keen edge and to 28 degrees for the stunt edge.

Use a coarse sharpening tool around 400 to 600 grit for your carving knives set. First step would be to reshape the edge, next focus on the sharpness of the edge.

The choice of the sharpening tools would depend on your needs and preferences:

- Whetstones

Versatility: Suitable for a wide range of carving tools.

Control: Helps maintain good control while sharpening.

Advice: Ideal for carvers who prefer traditional methods of sharpening and have some experience with it.

- Honing stones

Maintenance: Suitable for already sharp edges.

Simple: Very easy to use.

Advice: Great for regular maintenance between major sharpening sessions.

- Diamond sharpening stones

Durability: Very enduring and hard.

Efficiency: Fast cuts, suitable for dull carving tools.

Advice: A good option for those who need a durable and efficient tool.

- Sharpening machines

Speed: Fast and efficient.

Consistency: Minimal effort needed, provide consistent results.

Advice: Save a lot of time for those who already need to maintain lots of carving spoons tools.

Cleaning

For maintaining longer performance of your wood spoon carving tools, wipe your tools with a dry cloth after each use or use a soft brush to clean the blades. Lightly cover metal parts with mineral oil to prevent rust and apply linseed oil to wooden handles. Dry tools after each cleaning to avoid moisture accumulation. Develop a habit of inspecting your carving spoon set regularly and keep tools sharp.

Storage

Consider using a tool roll or a storage case to keep tools organized and protected from damage and moisture. Additionally, you may use protective caps for the carving tools like gouges.

Proper Use

It may sound quite obvious, but it is extremely important to use your wood carving tools for their intended purpose. Improper use may reduce their lifespan.

Wrapping Things Up

In the art of wood spoon carving, the choice of tools and proper tools care play a pivotal role. Following the maintenance rules mentioned above is crucial to enhance your carving experience and ensure the tools will serve you longer. These are the key takeaways:

Tool selection: When selecting wood carving tools, consider the type of wood you intend to use, design complexity, and your individual comfort.

Types of tools: Each tool serves its purpose. Most basic ones include straight, hook, sloyd knives and axes.

Maintenance: Regular and proper maintenance ensures better longevity and performance. Remember following safety recommendations to avoid injuries.

Skill enhancement: As your skillset grows, master new carving tools and techniques.

By following these best practices, you can ensure that your spoon carving projects will be successful. Happy carving!