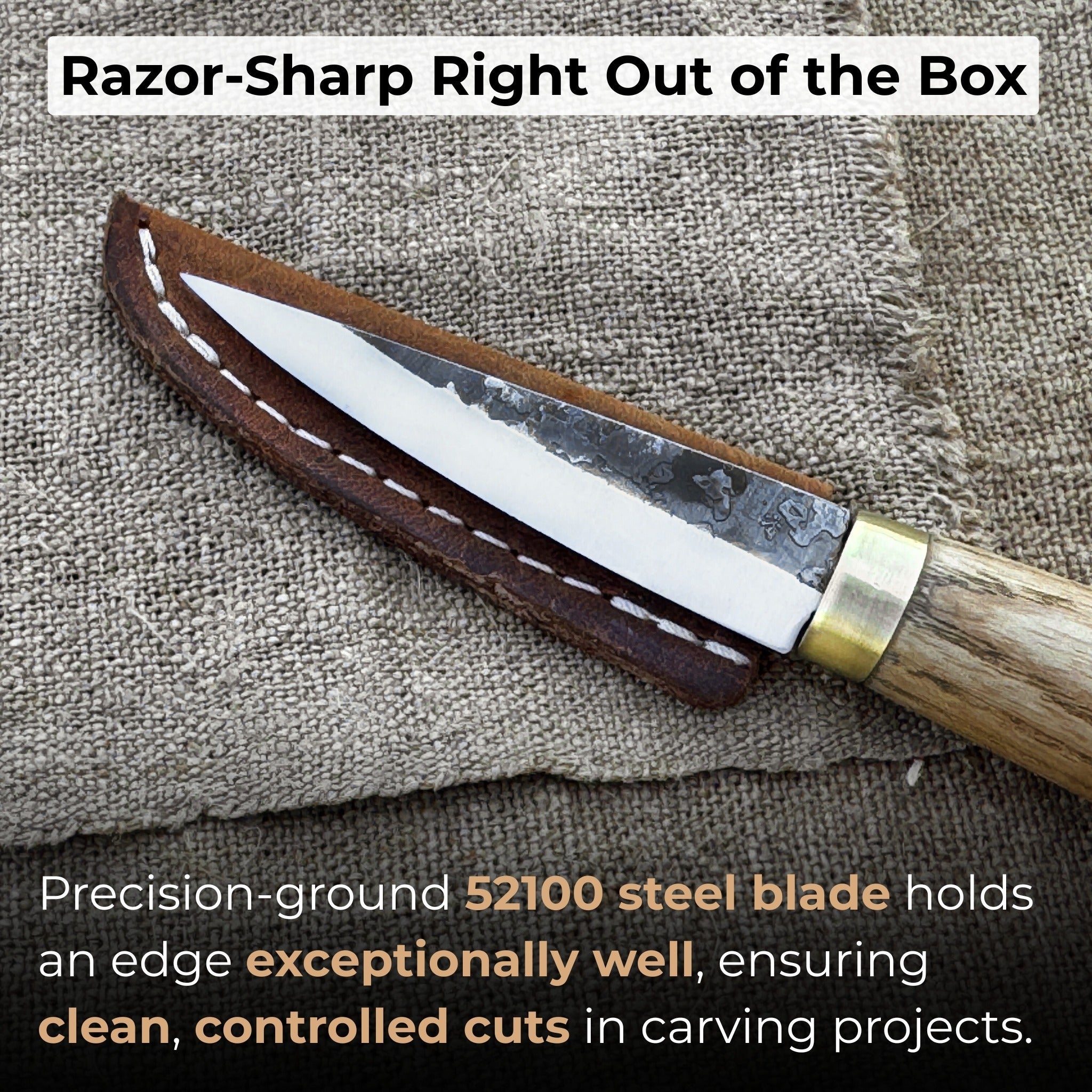

Whittling Sloyd Knife, 7.5 cm (2.95 inches)

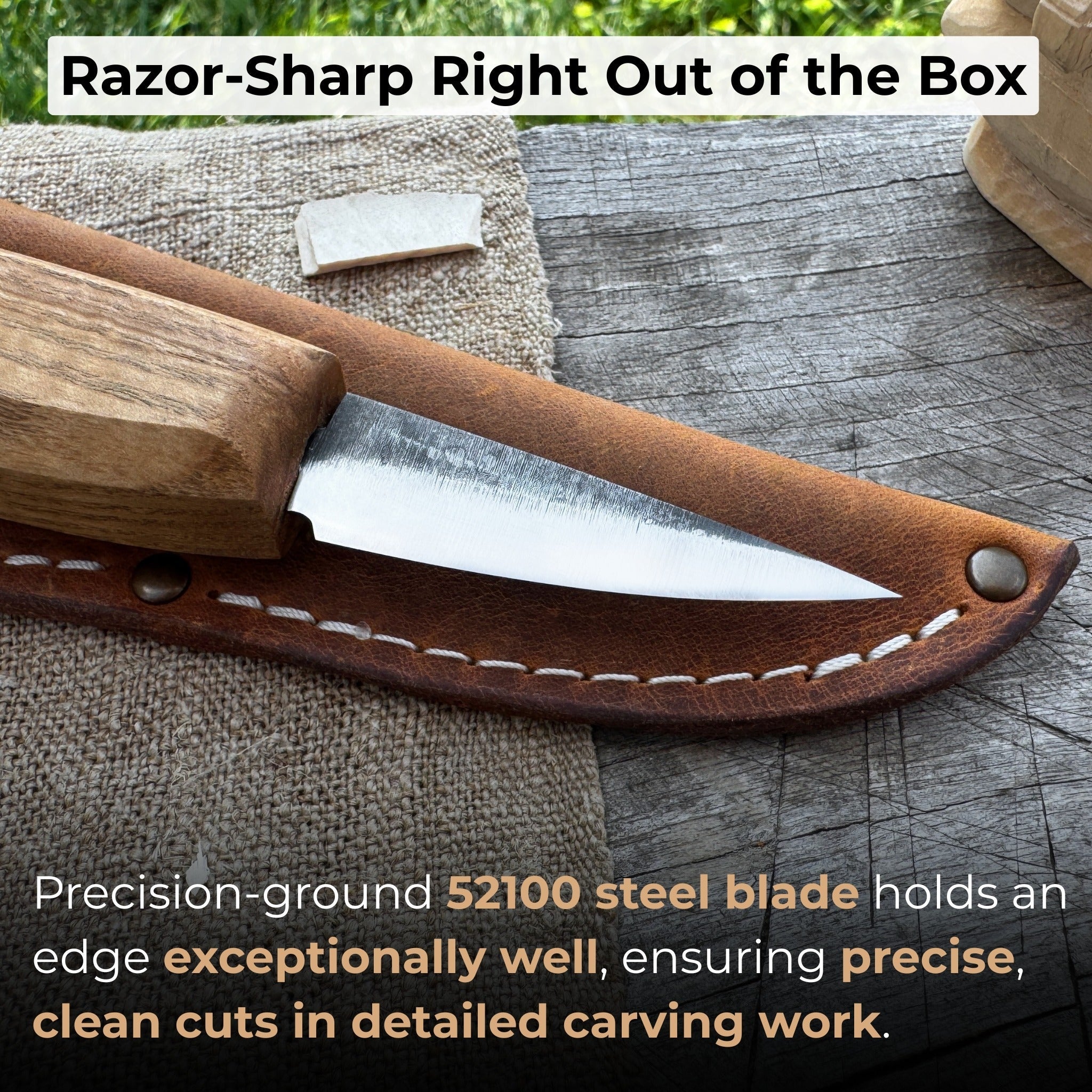

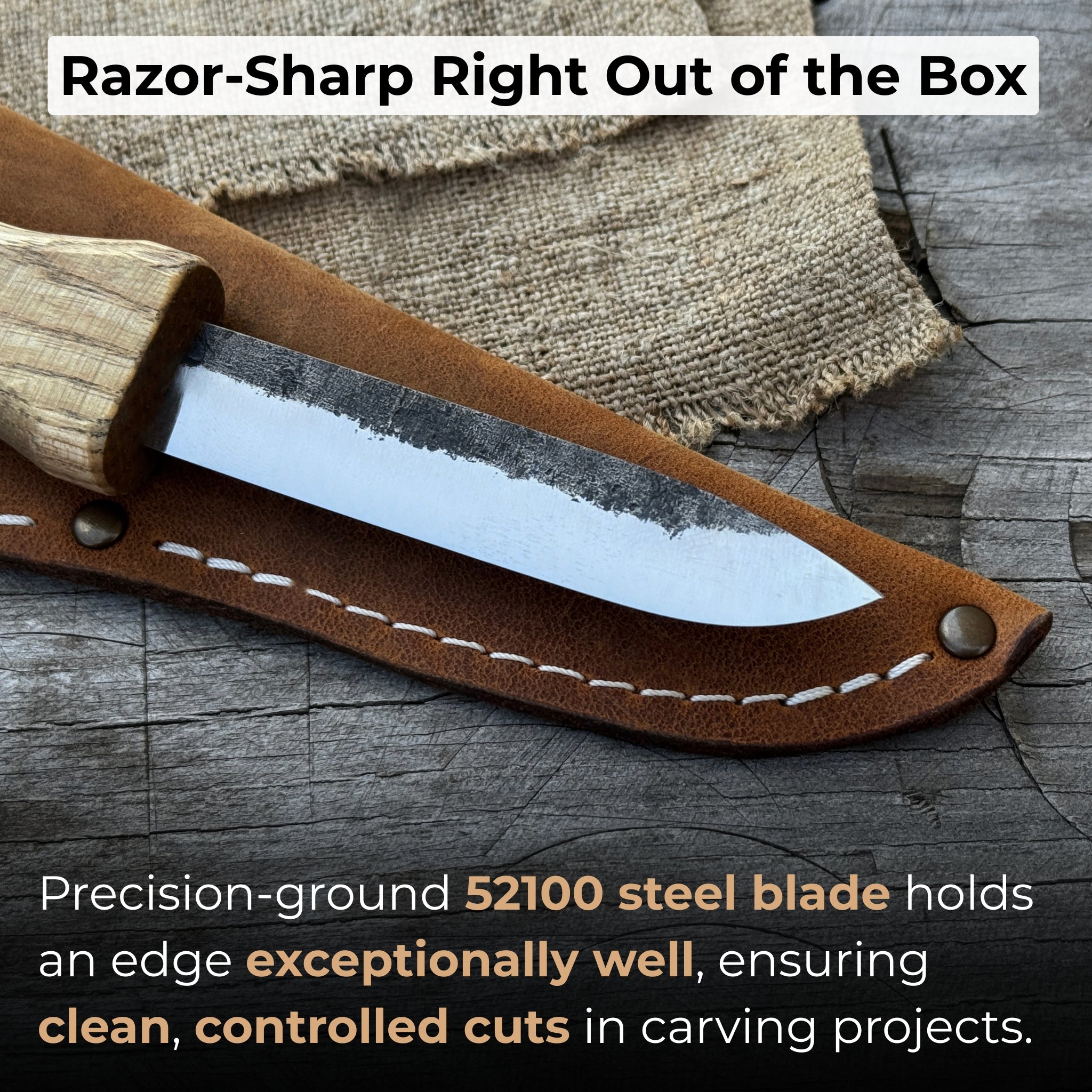

Hand-Forged Sloyd Knife, 7.5 cm (2.95 inches)

Hand-Forged Sloyd Knife, 9 cm (3.54 inches)

Small Sloyd Carving Knife, Blade 6.5 cm (2.56 inches)

Whittling Sloyd Knife with Leather Sheath, 7.5 cm (2.95 inches)

Key Characteristics of Sloyd Knives

To begin, a bit of background: the word “sloyd” comes from the Swedish word “slöjd”, meaning crafts. Essentially, a sloyd knife is a tool for crafts. “Sloyd” also refers to an educational system that trains new craftsmen in carving through simple, regular exercises.

The original sloyd knife (sometimes referred to as a classic knife) featured a full tang construction and a straight cutting edge with a tapered blade and a downward-angled front. The key characteristics of the traditional sloyd knife were simplicity and functionality. It’s been widely used for various woodworking tasks, from roughing out shapes to green woodworking.

Interestingly, most modern sloyd knives do not follow the pattern of the original design. Today’s sloyd knives are usually slightly curved, which makes them perfect for slicing movements. They are made from more durable and rust resistant materials like stainless or high-carbon stainless steel with average blade length between 2-3 inches. Such sloyd knives are easier to maintain compared to the traditional ones. They are also more versatile, so you can find a few that cater to your specific needs and help you create perfect projects.

So, what other types of sloyd knives are available on the market? Here’s a shortlist of the most commonly used:

Straight Blade Sloyd Knife

- Function: Mostly used to remove larger chunks of wood to carve out a general outline of a wooden figure. Great for making precise straight cuts along the grain. It is also widely used in whittling to cut off thin slices of wood and making V-shaped notches in the wood.

- Blade: As its name suggests, a straight carving knife features a blade with a straight cutting edge without any curves, which makes it perfect for precise cuts and more controlled motions.

- Handle: Hardwood handles offer durability and a firm grip. Handles made from composite materials are more humid resistant. Oval and rounded shapes of handles provide more natural grip.

Short Blade Sloyd Knife

- Function: This knife can become an irreplaceable element of your carving tools set if you often work on designs with intricate details. The compact size of its blade allows it to carve in very tight spaces. It is also commonly used in chip carving, creating clean cuts. If you work with soft woods a lot, a short blade sloyd knife is all you need, as it helps avoid over-cutting.

- Blade: The blade length ranges from 1.5 to 2.5 inches. The knife blade shape is typically straight and slightly curved with a pointed tip to make fine details look really clean. It usually has a single bevel edge that can be either flat for straight cuts or curved for smooth transitions.

- Handle: Hardwood of composite materials are preferable, as they make handles more durable and ergonomic. The shape of the handle itself should be proportional to the short blade – not too large and fitting well in the hand.

Long-Blade Sloyd Knife

- Function: Perfect for larger woodworking projects like camp tools, kitchen utensils, sculptures, and other decorative items. Thanks to its extended blade, it is also a great tool for whittling.

- Blade: Typically 3-5 inches long, allowing for better sweeping movements. The blade shape is usually tapered and pointed. Most of these knives have a Scandi grind, a type of knife grind with a single, flat bevel that runs directly to the cutting edge. The blade finish is polished, reducing cut friction and making it resistant to corrosion.

- Handle: Good quality long blade sloyd knives have rounded or textured grip that comfortably fit the hand and prevent accidental slipping. Made from hardwoods or composite materials, the handle will increase the tool lifespan.

Hooked Sloyd Knife

- Function: Used for carving projects that involve curved and hollow shapes like scoops, bowls, spoons, kuksa, and other decorative carvings. It can also help make more rounded transitions between details.

- Blade: The blade is hook-shaped with a slightly pointed and rounded tip that helps curve smaller details in tight areas with minimal effort. The cutting edge is usually single-edged. The depth of the hook can vary; some have a shallow curve, while others have a deep hook.

- Handle: Good quality models often use hardwood handles made from ash or birch.

- Versions: Right and left-handed models are specifically created for a dominant hand of a craftsman. Double-edged hooked knives are less common but allow carving in both directions.

Choosing the Right Sloyd Knife

Let’s now take a closer look at the characteristics that can help you choose the best sloyd knife:

Blade Materials and Their Benefits

Paying attention to the materials used in carving tools is important for several reasons. Blade material affects how long it remains sharp and retains a cutting edge. This, in turn, impacts frequency of maintenance - you won’t have to sharpen carving tools often if they are made from high carbon steel, for example. Blade materials have their specific applications too; knowing them can help you choose the best sloyd knife for your carving tools set. Some of the most widespread materials for knife blades are:

High Carbon Steel

- Advantages: Carbon steel blade is very durable and can retain edge well, reducing the need of frequent sharpening.

- Disadvantages: Requires regular care to prevent corrosion (cleaning and oiling).

Laminated Steel

- Advantages: Often uses hard core and softer outer layers to prevent corrosion. The hard core helps retain a cutting edge.

- Disadvantages: Complex to manufacture, which increases its price. If lamination has some imperfections, you might end up carving with low carbon steel. Laminated steel may make blades too thick to cut the wood.

Stainless Steel

- Advantages: Tough and durable, highly resistant to rust. Needs maintenance less frequently compared to high carbon steel.

- Disadvantages: May not retain a cutting edge for as long as high carbon steel.

High Carbon Stainless Steel

- Advantages: The best of two worlds, combining the advantages of carbon and stainless steel. Usually contains 0,6% carbon, which ensures high blade durability, while chromium content improves its resistance to corrosion and rust. Requires less maintenance in contrast to carbon steel.

- Disadvantages: Because of increased hardness, it may be difficult to sharpen. It cannot boast the same level of corrosion resistance as stainless steel, so it will require extra maintenance when used in humid environments.

Handle Design and Ergonomics

Handle material and design will directly influence how many hours you can spend carving wood. An uncomfortable grip may lead to hand fatigue. So, you may need to try out different shapes, sizes, and materials of handles before you find the perfect one.

Handles are typically made from hardwood, making them comfortable and repairable. An oval shape usually fits the hand well and ensures you can spend hours carving. These handles may require more regular maintenance than the ones using composite materials.

Composite materials (rubber or plastic) make handles more durable. They are also lighter and need less maintenance than wood handles. These handles may offer additional comfort thanks to its non-slip textures. However, composite handles can be more expensive.

Size Variations and Their Uses

When choosing sloyd carving knives, it is crucial to understand what their main uses are and which of them could be better for a specific project. In summary, here’re the key specs you may need to consider:

Blade Shape

Straight blades are made for general woodworking, clean cuts, consistent designs and fine detail work. Curved and hooked blades, in turn, allow for concave cuts, hollowing, and adding smooth details.

Blade Length

Everything is simple here. Shorter blades are great for detailed work that requires high precision. Medium length blades (3-4 inches) are used for versatile woodworking, including beginner wood carving projects. Larger blades (more than 4 inches) are mostly used for roughing out shapes and removing large pieces of wood.

Handle Shape and Size

The most common handle size for a sloyd carving knife is between 4-5 inches. It offers a secure grip and comfort. Usually, the diameter of the handle that would fit most of the craftsmen varies from 1 to 1.5 inches. Sloyd knives with these handles would be suitable for almost any general wood carving project. When a project involves removing large portions of wood, longer handles may be a better choice.

How to Use Sloyd Knives Safely and Effectively

And a few concluding tips to gain a great satisfaction from your work. When you start carving wooden surfaces, remember to always take safety measures and use proper carving techniques to prevent the risk of accidental cuts. Some of the most essential safety and maintenance tips are below:

Basic Handling and Safety Tips

Hand Position and Grip. Make sure fingers wrap the handle firmly and comfortably. Use thumbs to make control cuts.

Wood Carving Direction. Carve away from your body; practice slow and controlled movements.

Safety equipment. Wear carving gloves and thumb guards, or use safety tape for your fingers.

Techniques for Precision Cutting

Guiding. Use a non-dominant hand to hold and direct the tool when carving.

Marking. Outline your future design on the wood piece with a pencil or marking tool for better precision.

Clamping. Before trying hand-held techniques, start carving a wood piece that can be clamped to a sturdy table. You may choose something as simple as a bench hook or a portable lightweight vise or clamp. This way, you will gain more control over the project, free up your hands, and reduce the risk of injuries. Clamps and vises are especially helpful when you carve intricate designs, letting you rotate the workpiece the way you need.

Templates. For repetitive patterns and high precision, use cutting jigs. They will help you carve accurate patterns.

Maintenance and Care for Longevity

Sharpening. The frequency of sharpening depends on how often you carve and also on the quality of your tools. Use sharpening stones with a grit of around 1000 to maintain a proper edge if it has dulled, and then apply a finer grit (3000-8000) for finishing. Diamond stones are great for quick sharpening, while stropping with leather can be an effective choice between carving sessions to quickly refine the edge.

Cleaning. Remove all the dirt and wipe a sloyd knife with a dry piece of cloth to prevent rust.

Oiling. Apply mineral oil to the knife blade after cleaning, and use linseed oil or beeswax on the wooden handle.

Storage. There’s nothing better than a dry storage environment for carving tools. Anything from tool rolls to toolboxes, and cabinets can serve as good organizational solutions.

Inspection. Regularly check the condition of blades and handles. Promptly remove any signs of wear or damage.