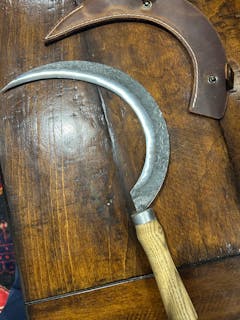

Small Stock Knife - Cloggers knife

Medium Stock Knife - Cloggers knife

Large Stock Knife - Cloggers Knife

Introduction to Hand-Forged Stock Knives

Stock knives originated in rural European communities around the 12-13th centuries. These sturdy tools were used by craftsmen in woodworking and clog-making, which is why they were also referred to as cloggers knives. In Medieval England, France and the Netherlands, cloggers used stock knives to shape wooden soles from rough wood blocks. These knives featured large, curved blades attached to workbenches, requiring pivoting motions for powerful cuts. The craftsman would pull the knife towards themselves while holding the wood against a stop.

As stock knife craftsmanship evolved, this tool was applied in chair making to shape spindles, legs, and other parts. Farmers used stock knives to repair their own tools, as they were ideal for shaping and smoothing wood to create durable handles, baskets for transporting produce, and stakes and posts for fencing. A stock knife became an irreplaceable assistant in chopping up roots and vegetables for livestock feed.

In leatherworking, stock knives were used to cut thick leather and prepare hides, as well as to create harnesses and other leather gear for horses.

Most modern stock knives retain their original design, making them suitable for many traditional crafts and for those who value hand-crafted methods.

Sharky Forged Steel Tools™ follows the long-established traditions of hand-forging and offers a selection of custom stock knives with total lengths ranging from 49 to 89 cm (19.3 to 35 inches). With blades in different shapes (straight and rounded) and handles in either T-shaped or straight designs, our stock knives provide excellent leverage. For better versatility, you can choose a hand-forged stock knife with attachments, allowing for adjusting blade positions and adding auxiliary blades, making it perfect for woodworking or leatherworking.

Key Features of Our Stock Knives

Blade Materials and Construction

Crafted using advanced hand-forged blade technology, each blade is made from high-quality 52100 carbon steel, making it suitable for various tasks, from cutting clogs to slicing green wood. The hand-forged stock knife featuring this type of steel offer several advantages:

- Hardness: 52100 steel standard is known for its high hardness (Sharky Forged Steel Tools™ tools feature 59/62 HRC). This positively affects the longevity of sharp edge retention.

- Wear Resistance: It is extremely durable, resisting stress and fractures. The steel also resists abrasion and retains its high performance qualities under repeated heavy use.

- Corrosion Resistance: While not as corrosion resistant as stainless steel, 52100 steel is less prone to rust due to its chromium component. Applying protective treatments to the steel is necessary to prolong its efficiency.

- Ease of Sharpening: 52100 steel produces durable forged knives with excellent edge retention. Due to its high durability, it may require special sharpening methods but it responds well to the right tools. Recommended sharpening tools include whetstones (waterstones/oilstones) or diamond stones for initial sharpening, leather stropping with polishing compound to refine the edge, and honing with a ceramic or steel rod between sharpening sessions.

Our high-quality stock knives are crafted with versatility and performance in mind. Each hand-forged stock knife comes in varying construction types to suit a range of tasks:

- Made from a single piece of metal with a t-shaped handle

- Featuring a blade attached to a straight wooden handle

Blades are available in both straight and rounded shapes. Straight blades are ideal for making precise, clean cuts in wood, dowels, and clogs, while rounded blades excel at shaping and smoothing curved surfaces, such as bowls and spoons.

Available in different lengths, from 49 to 89 cm (19.3-35 inches), these stock knives offer varying leverage to accommodate different cutting needs and preferences.

Handle Design and Comfort

Ergonomic design makes each stock knife simple to handle and equally suited for both beginner and advanced craftsmen, whether right- or left-handed.

Each handle is made from ash wood, chosen for its stress resistance, good shock absorption, comfortable grip, and ease of maintenance.

The choice between a T-shaped handle and a straight handle in our hand-forged stock knife depends on the task. T-shaped handles offer superior control and leverage for heavy-duty cutting, while straight handles provide comfort and stability for finer, detailed work.

Selecting the Perfect Hand-Forged Stock Knife

Factors to Consider for Different Applications

When choosing a stock knife, it’s essential to first identify the specific projects the tool will be used for. Different applications may require different tool lengths, blade shapes, and handle designs. Consider these aspects:

- Blade Material: Knife materials define the tool’s overall efficiency. High-carbon steel is most commonly used in high-quality stock knives because it provides excellent edge retention and sharpness. When selecting this steel, pay attention to the Rockwell Hardness rating (56-62 HRC is considered the industry standard).

- Blade Design: Straight blades are made for bulk removal of the material and cutting straight lines. Curved blades are better suited for detailed cuts. Choose the one that fits your task.

- Handle Design: Material like wood or rubber provide more comfort.

- Edge Grind: A stock knife with a flat grind is best for making thin cuts, a convex grind is ideal for cutting thicker materials, and a hollow grind provides a sharper edge.

- Maintenance: Consider how easy it is to maintain a sharp edge. Some steels, like high-carbon steel, may require frequent sharpening but can achieve a sharper edge compared to other stock knife steels.

Comparing Hand-Forged Knives to Machine-Made Alternatives

Both hand-forged knives and machine-made stock knives go through a forging process, but they differ in quality and production methods.

Hand-Forged Knives:

The forging process itself differs from the automated process, which is why a hand-forged stock knife usually turns out more durable and sharper compared to a machine-made knife. The grain structure of the steel is improved during hand forging, enhancing edge retention and making the knife sturdier. Other hand-forged knife advantages include ease of sharpening, better materials, and more options for customization. As a rule, these knives are more wear-resistant and stay sharp longer. Athough hand-forged knives may come at a higher price, they can still be found in knives sales.

Machine-Made Knives:

These knives are typically cut and grinded from pre-formed steel. Even though this process is more efficient, it doesn’t allow the steel to achieve the necessary level of refinement. The blades can still be sharp and tough, but they are more likely to dull faster than hand-forged knives. Produced on a large scale, they are usually more affordable, but it all depends on the brand and its reputation. Machine-made stock knives are generally more likely to break under pressure.

Conclusion and Cases in which the Stock Knife is used

Hand-forged stock knives are traditional tools still used in woodworking and leather crafts. One of their key benefits is long-lasting performance and excellent edge retention. Tools made by Sharky Forged Steel Tools™ combine quality materials with affordable prices, challenging the myth that hand-forging tools are prohibitively expensive.

The hand-forged construction makes stock knives suitable for demanding tasks such as cutting thick materials or smoothing wood. In addition to clog-making, stock knives handle a great variety of tasks, including carving clogs and handles, green wood carving, crafting chair spindles, slicing wood along the end grain, and removing large chunks of the material.