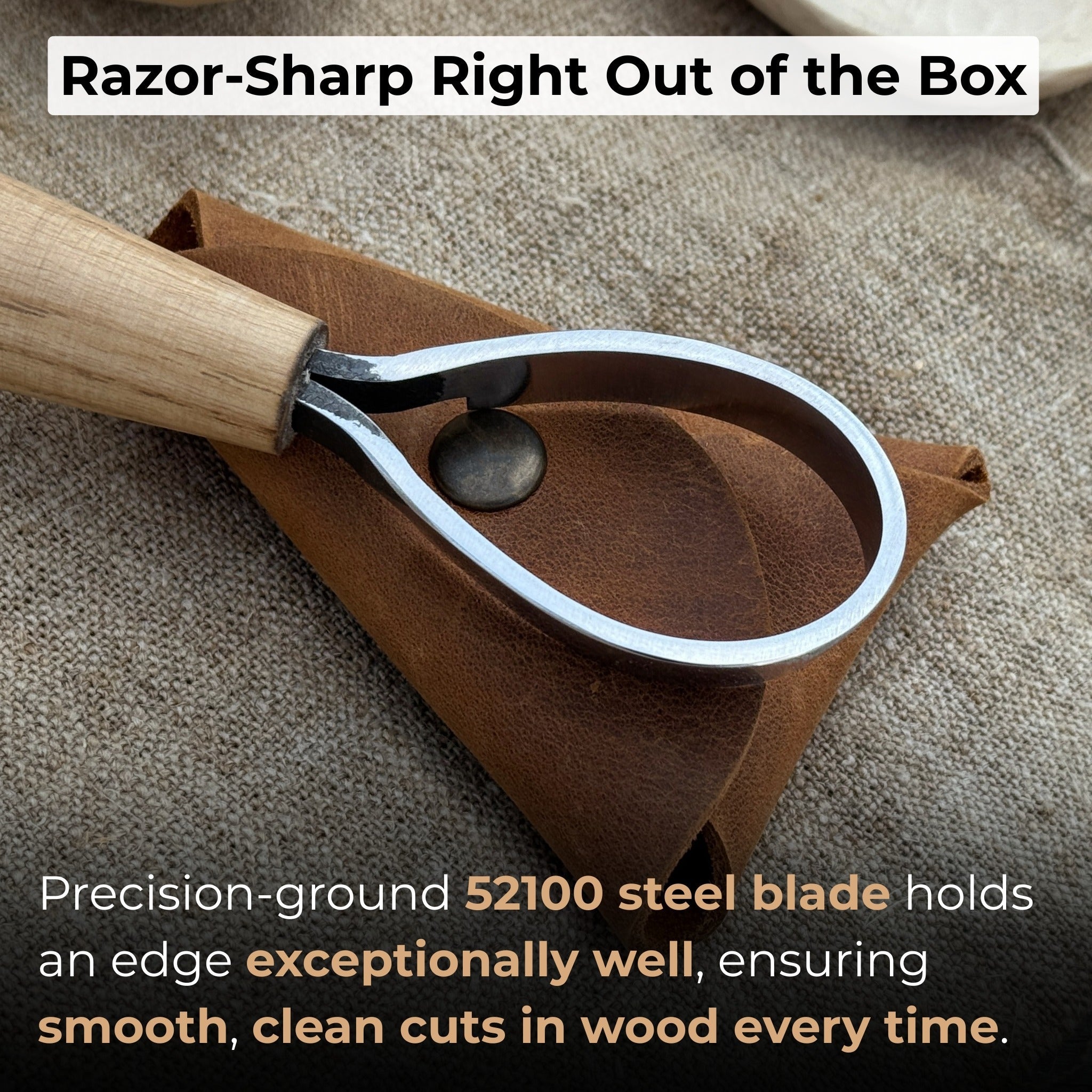

Spoon Carving Scorp Knife, ⌀3.5 cm (1.4 inches)

Spoon Carving Scorp (Round) Knife, ⌀3 cm (1.2 inches) with Leather Case

What is a Scorp Knife?

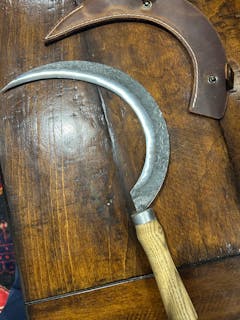

Traditionally, a scorp tool, also known as inshave, was used by barrel makers. Its ability to remove wood in bulk made it invaluable for carving out barrels and other similar containers like tubs or troughs.

The application of a scorp woodworking tool today boils down to any wood carving project that requires hollowing out over wide areas, including carving out spoons, bowls, kuksa cups, chair seats, and more.

The scorp’s blade is significantly curved, which helps remove wood easily with a scooping motion. The hand tool stands out from other tools like gouges and hook (spoon) knives with two more unique features:

Blade Curvature

- The horseshoe-shaped blade (loop) allows for deep, precise carving when working on smaller projects.

- The U-shaped blade is usually wide and more suited for hollowing out chair seats or large bowls.

Handle Design

- Scorps with horseshoe-shaped blades often have single handles, making it easier to hold the workpiece with the other hand. With a single-handled scorp, you may not even need a separate left- and right-handed spoon knife, as all roughing out and finishing can be done with a single tool.

- U-shaped carving tools usually come with two handles for better control and leverage. They help make controlled pulling motions and speed up roughing out wood.

Key Features of Scorp Knives

It’s the blade curvature that makes the scorp knife stand out. The loop-shaped blade helps in cutting wood without digging too deep, making the workpiece lines look really smooth. The blade shapes come in a range of sizes. You may come across these:

- Tight Curve: A sharply curved blade for small, deep cuts like spoon bowls.

- Medium Curve: A balanced curve for general hollowing tasks like medium-sized bowls and scoops.

- Shallow Curve: A gently curved blade for large, shallow hollows like chair seats and wide bowls.

- Asymmetrical Curve: A blade with a steeper curve on one side for tricky angles and varied depths in specialized carvings.

The ease of scooping with these carving tools also depends much on the bevel type. A single-edged scorp tool allows for more precise, controlled cuts, whereas double-edged blades enable you to cut in both directions, which is especially helpful in large projects.

When it comes to blade materials of a spoon scorp, the preferred choice is high-carbon steel. It is well known for its long-lasting performance and ability to retain sharp edges under heavy use. It is also a very universal material, as it can perform effectively on soft and hardwoods.

Now, the handles. Good ones are often made from hardwood like oak, ash, or walnut. They usually feature oval or rounded profiles to fit the hand well and minimize pressure points.

Benefits of Using a Scorp Knife

Crafted from quality materials, scorp knives will serve you for a long time, giving the right balance of control, power, and comfort. If we were to speak about two broader scorp tool categories, the advantages would be as follows:

Single-Handled Scorp Knife

- Perfect for Small Spaces: Great for detailed work like carving spoons and bowls.

- One-Hand Operation: Efficient and convenient.

- Precise Cuts: The loop design helps you make fine, controlled cuts.

- Portable and Handy: Easy to carry, perfect for quick carving sessions.

- Easy to Use for Beginners: Can be safely used by beginner carvers and hobbyists.

Double-Handled Scorp Woodworking Tool

- Strong and Efficient: The double-handle design gives you more power for larger cuts and deeper hollows.

- Comfortable to Use: Reduces hand fatigue during long carving sessions.

- Smooth and Consistent: Ideal for large, smooth cuts across wider surfaces.

- Safe and Precise: Two-handed grip for better control and stability.

- Suitable for Professional Woodworkers: Simple in technique and effective when working on larger woodworking tasks.

Overall, while there is a learning curve, with practice and patience, you can become proficient in using a scorp tool within a short timeframe.

How to Choose the Right Scorp Knife

Now, how do you know which spoon scorp matches your project? We recommend evaluating the project’s scope and the materials you will be working with first. Next, explore the quality scorp knife options. To find your best match, here are a few more selection criteria:

Blade Size and Curvature

Blade size and curvature influence the smoothness of the lines and the integrity of the entire work. Let’s explore how different blade sizes match different types of projects based on the range of tools offered at our online shop, Forged Steel Tools:

- A smaller blade diameter, ranging from 3 cm (1.18 inches) to 6.5 cm (2.56 inches), is suitable for intricate spoon carvings. This allows for precise control and detailed work.

- For larger projects, such as bowl carving, a larger blade diameter, from 9.5 cm (3.7 inches) to 19.5 cm (7.68 inches), is more preferred.

The curvature of the blade also plays a crucial role; a deeper curve is better for hollowing out deeper cavities, while a shallower curve is suitable for more surface-level carving.

Handle Material and Design Comfort

The handle material and design impact the comfort and control over the tool. Forged Steel Tools make handles from ash wood to ensure durability and shock absorption. These hardwood handles are lightweight and comfortable. Their oval shape fits the natural curve of the hand, which is crucial during long hours of work.

Quality and Craftsmanship

Investing in high-quality, hand-forged tools pays off with time. Our hand-forged spoon knives and inshaves are crafted from 52100 carbon steel (ASTM A295 standard), providing exceptional edge retention and wear resistance. Each tool comes pre-sharpened and ready for immediate use.

Contact us for individual advice, we are always ready to assist via chat, contact form, or email.