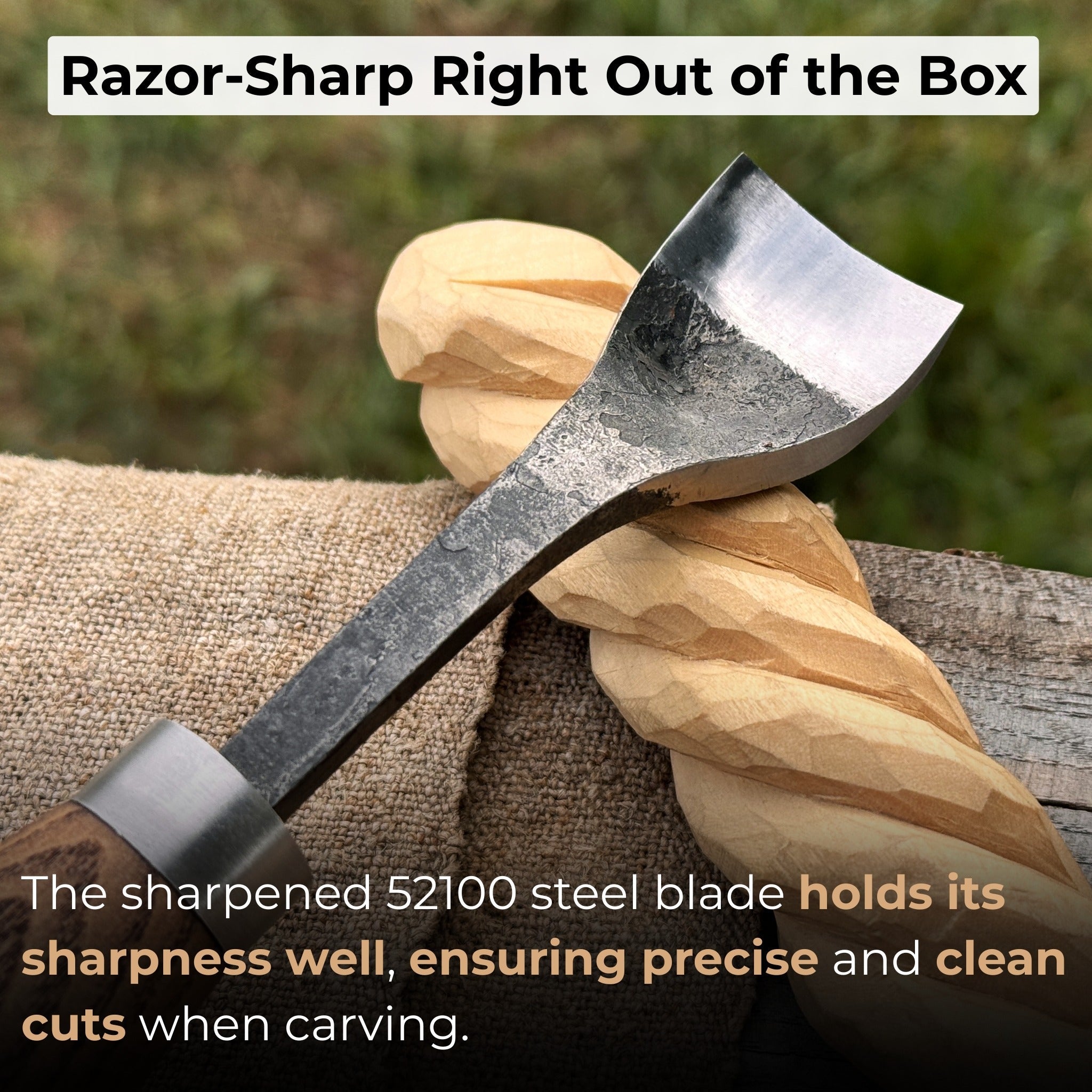

Spoon Bent Gouge, 20 - 45 mm (0.8 - 1.8 inches)

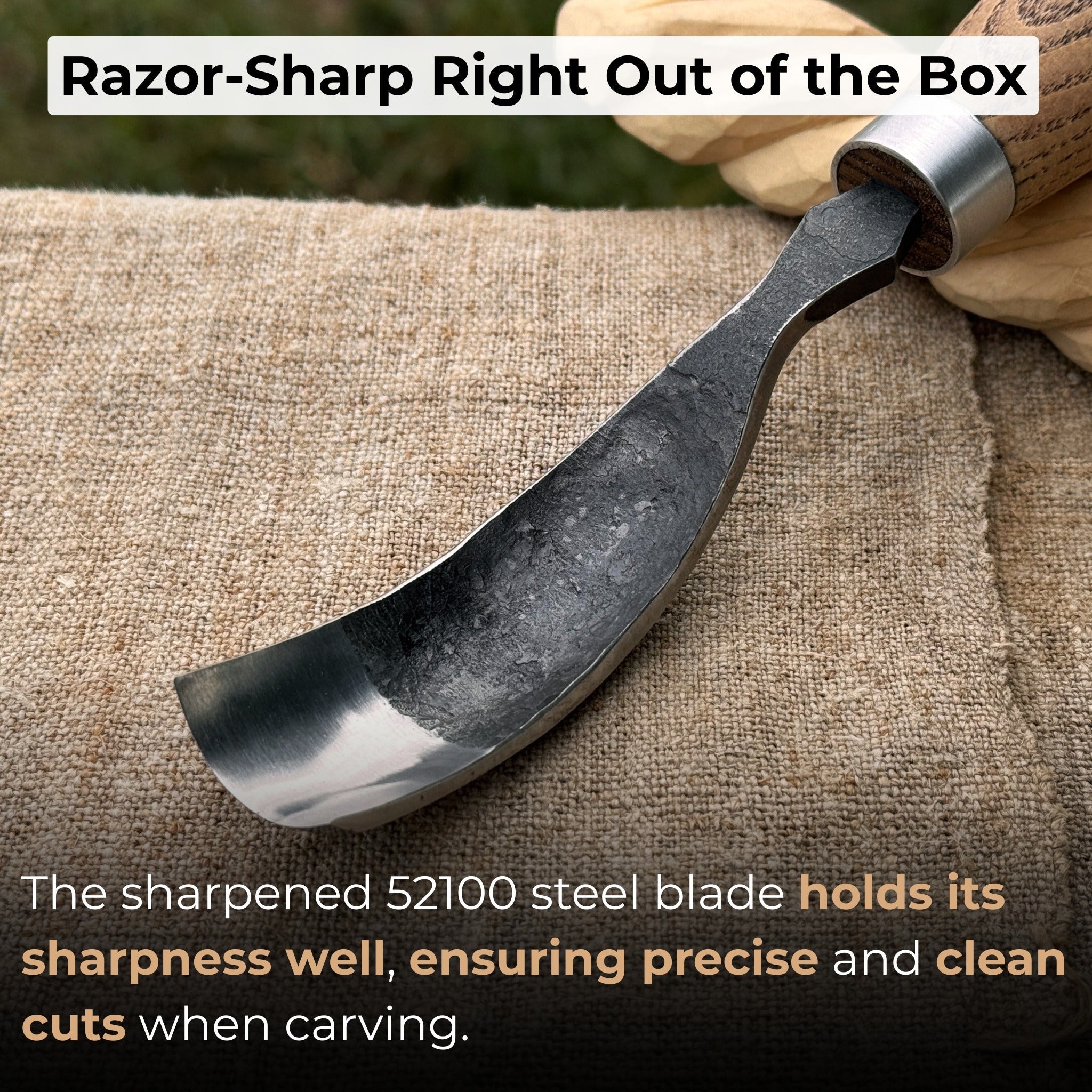

Long Bent (Curved) Gouge, 10 - 45 mm (0.4 - 1.8 inches)

Curved Bowl Gouge, 10 - 45 mm (0.4 - 1.8 inches)

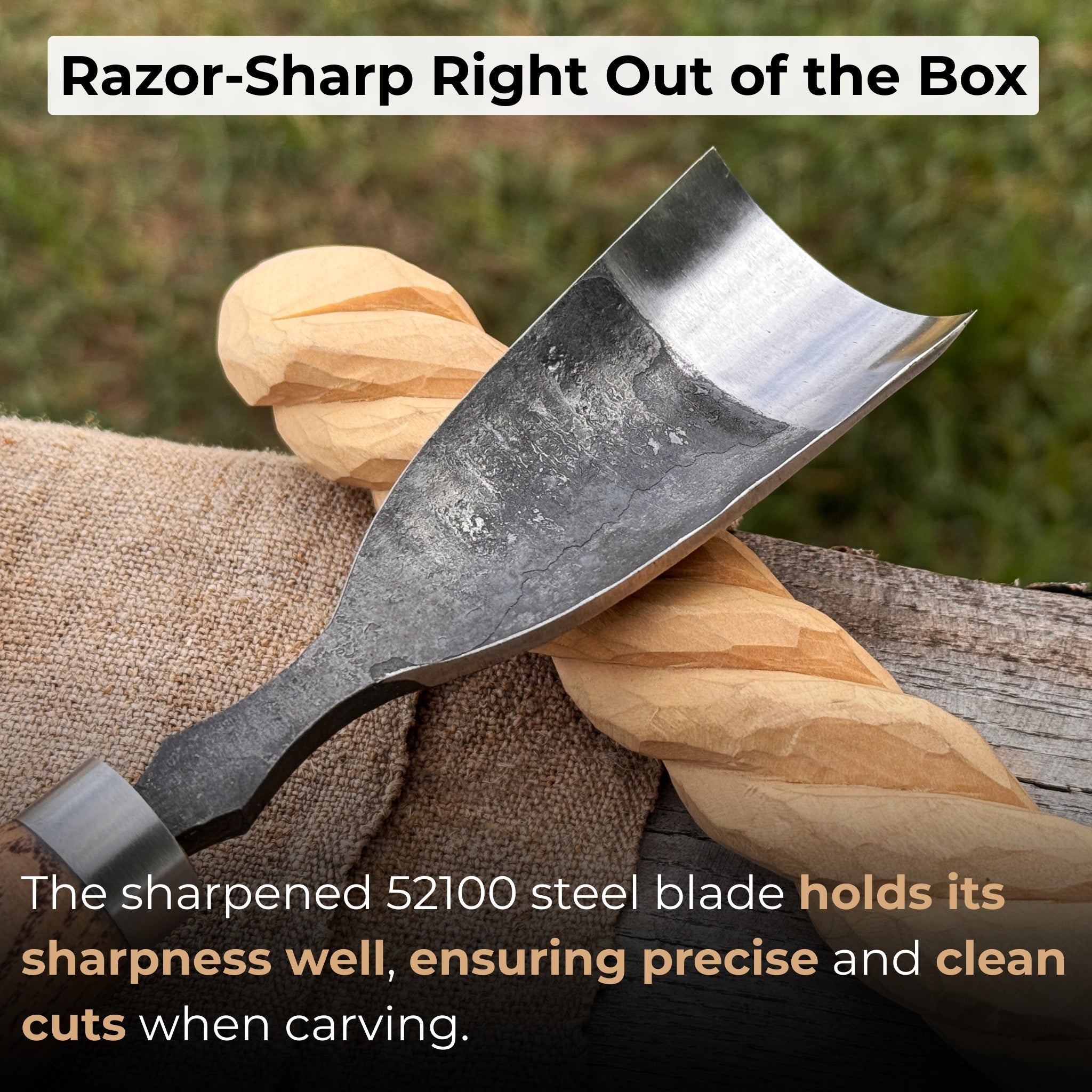

Straight Gouge (Rounded Chisel), 10 - 45 mm (0.4 - 1.8 inches)

Large Straight Gouge (Rounded Chisel), 10 - 45 mm (0.4 - 1.8 inches)

Spoon Bent Gouge, 50 - 70 mm (2 - 2.8 inches)

Spoon (Short) Bent Gouge, 50 - 70 mm (2 - 2.8 inches)

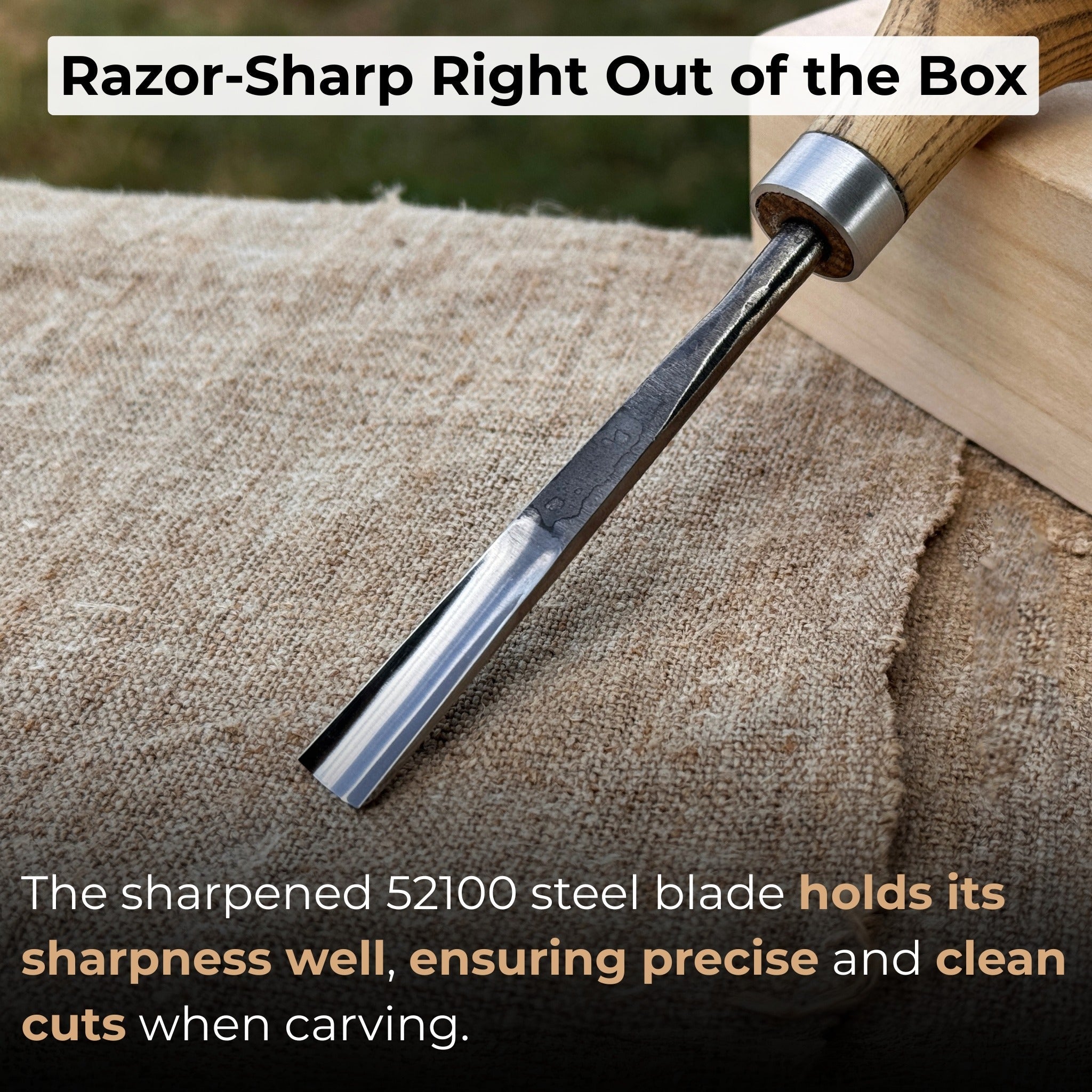

Straight Wood Carving Gouge, 5 - 12 mm (0.20 - 0.47 inches)

Bent Carving Gouge with Palm Handle – 8 mm / 12 mm (0.31 / 0.47 inches)

Curved Detail Carving Gouge – 8 mm / 12 mm (0.31 / 0.47 inches)

What Are Bent Gouges?

Chisels, V-tools, and gouges might seem similar, but they each serve different purposes. A chisel has a rectangular shape with a flat, straight cutting edge. A V-tool, or parting tool, has two straight edges that meet at a point, forming a “V” shape. A gouge, on the other hand, features a curved cutting edge.

The curvature of bent gouges is highly versatile, ranging from shallow to more pronounced curves. Manufacturers often classify carving gouges by shape and size using a numbering system. A lower number indicates a shallower curve, while a higher number indicates a deeper curve. For example, #1 - #3 have almost flat curves, #5 has a moderately curved edge, and higher numbers like #7 or #11 are deeply curved gouges. The second number used in the classification of bent gouges indicates the width of the cutting edge in millimeters. For instance, #7/10 would have a deep curve (sweep #7) and a cutting edge that is 10 millimeters wide.

The main application of gouges for wood carving is to reach and carve difficult-to-access areas, create concave shapes, add depth and dimension to designs carved on flat surfaces, and perform other sculpting tasks.

Types of Bent Gouges

Among the various carving tools a woodworker uses regularly, woodcarving gouges stand out for their ability to navigate challenging angles and tight spaces. They come in several variations, each serving a particular purpose.

Deep Bent Gouges

- Hollowing out shapes: Deep bent gouges are made for carving the interiors of bowls, spoons, sculptures that require deep, rounded cavities.

- Undercutting: This method creates a 3D effect in carvings by removing wood from underneath the overhanging sections of the design.

- Shaping convex surfaces: These wood carving gouges are also suitable for smoothing convex surfaces, especially in areas with intricate curves.

Shallow Bent Gouges

- Shaping and smoothing: These woodworking gouges create smooth transitions between different layers of a design, adding a polished finish to concave and convex shapes.

- Surface detailing/light undercutting: These tools help add fine details and textures to surfaces, creating gentle, shallow contours.

- Finishing work: These gouges add finishing touches to carvings, helping achieve a more polished look.

Specialized Bent Gouges

- Spoon carving: Specialized bent gouges with pronounced curves help achieve smoothness inside spoons or bowls.

- Precision carving: The curved blades allow for controlled depth in carving. Depending on the type of curvature, a woodworker can make shallow or deep cuts with high accuracy. These woodworking gouges also help create sharp edges, defining boundaries with stop cuts.

- Decorative effects, fine details, sculpting: The versatility of blade shapes enables the creation of various decorative designs. They can add details in areas of varying depth, working around obstacles.

Choosing the Right Bent Gouge for Your Project

The market offers a wide selection of gouges for wood carving, but how do you choose the ones you need? While it’s nice to have a broad variety of tools, it’s not necessary to have every type. You might start with a few essential gouges like #3, #9, and #11, and then expand your collection based on the specific needs and preferences. Key selection criteria include:

- Blade material: High-carbon steel and ball-bearing steel are perfect for their durability and sharpness. (Ball) bearing steel is particularly known for its high hardness and wear resistance.

- Blade shape: The blade curve should match your project. Deeper cuts can be made with longer bent gouges, while short bent gouges are more suited for detailed tasks. A deeper curve allows for steeper cuts, while a shallow curve is better for gentle shaping.

- Blade width: As numbered carving gouges come in various widths, they can be used in small and large carvings depending on the blade’s width.

- Handle ergonomics: Look for ergonomic handles that fit your hand. A good grip ensures long hours of carving and guarantees satisfaction with your work. Remember, long handles provide more leverage for deep carving, while shorter handles should be used in detailed projects.

- Matching project to the type of gouge: Consider the type of work you plan to do and choose accordingly. For hollowing out work, select deep bent gouges; for fine details, go for shallow bent gouges.

- Flexibility: Some tools may serve multiple purposes. If you want a general-purpose tool, select a woodcarving gouge with a moderate curve and width.

- Budget: Investing in a high quality tool is important, but it doesn’t mean you need to have an entire set of tools at once. Highly specialized tools can be worth investing in as experience grows or when you decide to take on large, complex projects.

Caring for Your Bent Gouges

Proper storage and maintenance will prolong the lifespan of your woodworking gouges and ensure their sharpness. When it comes to storage, you may come across a wide range of options, from plastic organizers to magnetic tool strips. Whether you have a dedicated workspace or need more flexibility to take your tools with you, leather or canvas tool rolls may be the most optimal solution:

- Protection: Tool rolls provide individual pockets for each carving gouge, preventing accidental bumps and nicks on the cutting edge.

- Portability: Unlike tool cabinets, tool rolls offer flexibility when a woodworker needs to change working stations.

- Flexibility: Tool rolls can fit into various spaces or even be hung up on the wall. They can be rolled up or laid flat, and many allow for customization to suit your specific gouges.

- Durability: Quality leather and heavy-duty canvas are long-lasting materials that prevent rust, damage, and dust.

To keep your wood gouges in good condition, follow these maintenance and sharpening tips:

Maintenance

- Cleaning: Use a brush or cloth to remove wood chips from the blade and handle after each use.

- Preventing rust: Apply oil to the blade to prevent corrosion.

- Proper storage: Ensure your storage is dry and protects the cutting edges properly.

Sharpening

- Sharpening stones: Use flat stones of grit sizes 250, 600, and 1200. Start by lubricating the stone with a fluid like an auto glass cleaner for smooth sharpening. Next, roll the gouge along the bevel on the stone in both directions. Use this technique on various stone grits to achieve a proper level of sharpness on the entire bevel. Remove burrs with a piece of abrasive leather, then polish the gouge on a strop.

- Figure-of-eight technique: This method sharpens the entire edge by moving the gouge in a figure-eight pattern on the sharpening stone.

Why Choose Our Bent Gouges?

At Sharky Forged Steel Tools™, you will find a wide selection of quality tools at reasonable prices. The craftsman behind this forge has years of experience in manufacturing durable and high-quality tools.

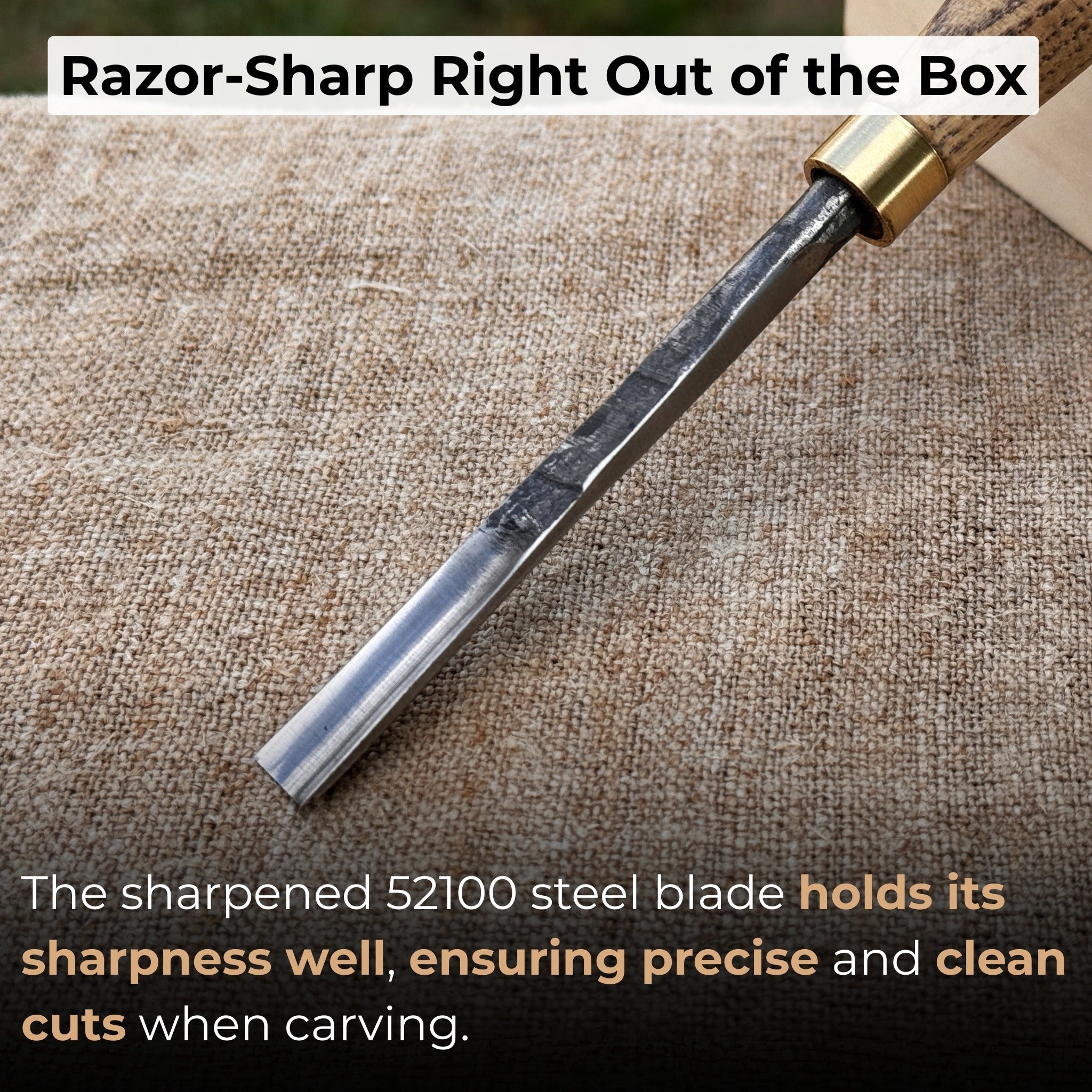

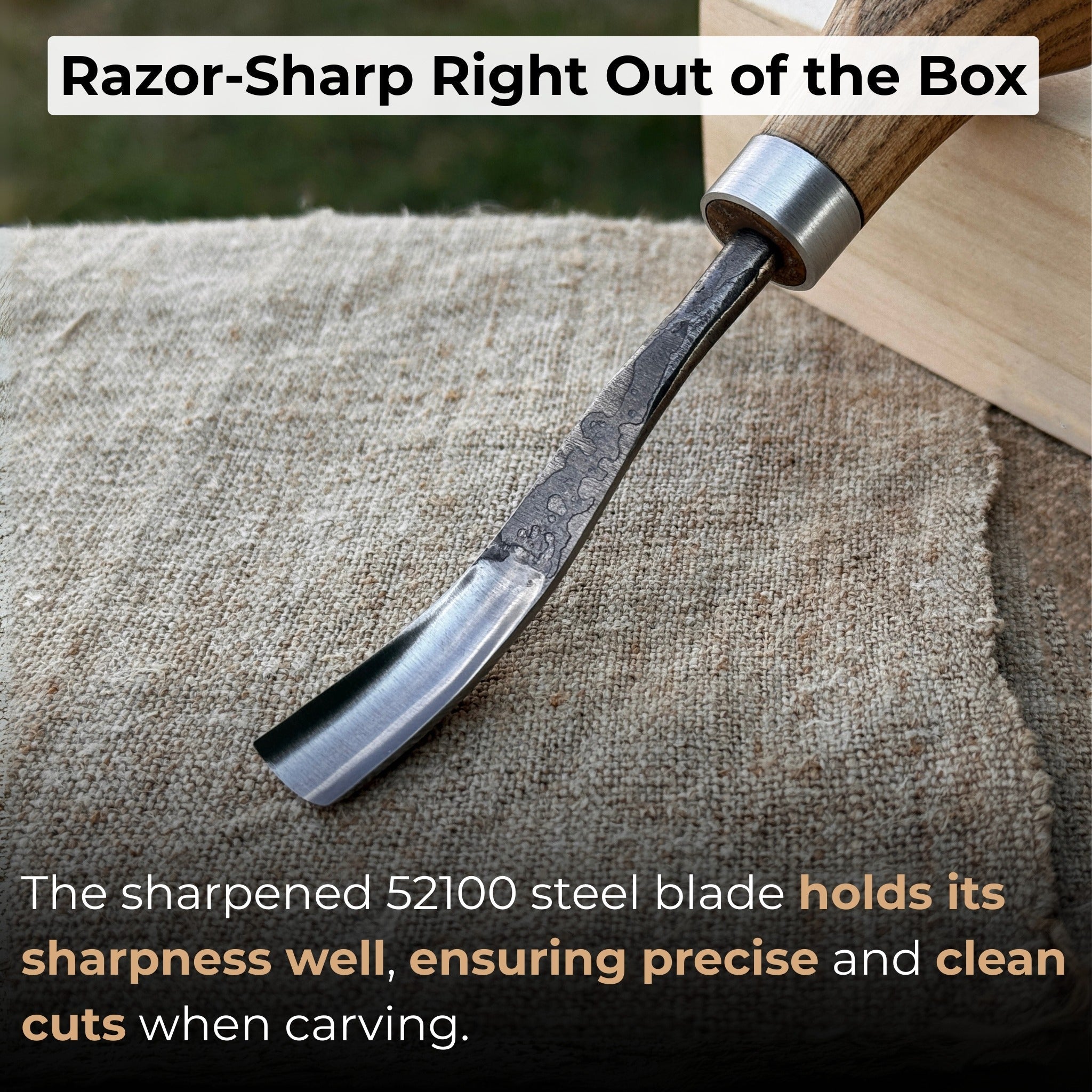

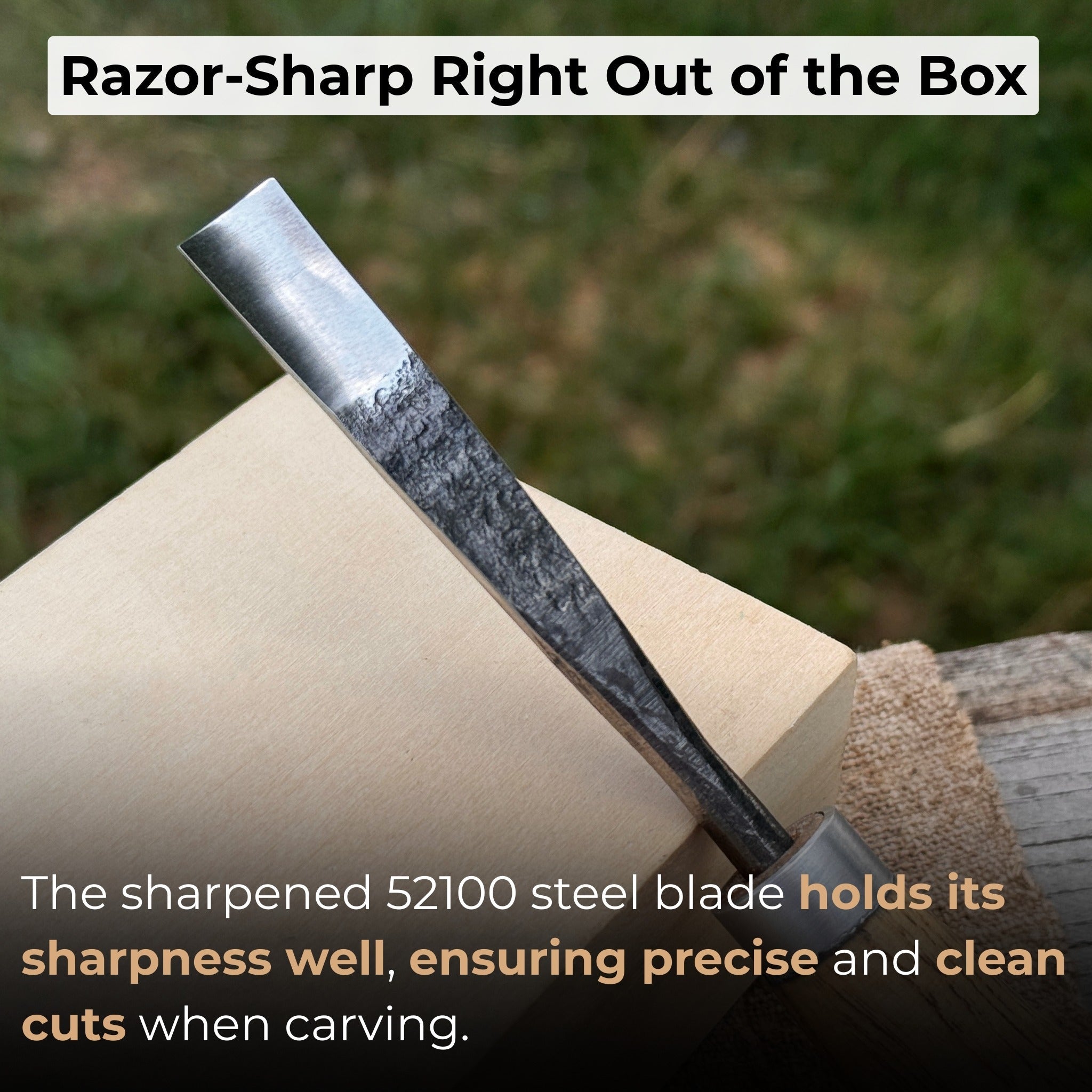

Our gouges come sharp and ready to use straight out of the box, so you won’t have to spend hours assembling or sharpening them.

All the gouges are hand-forged from hardened carbon steel 52100 (with a hardness of 59/62 HRC) to guarantee durability, sharpness, and satisfaction when working with both hard and soft woods. The handles are made from ash wood, chosen for its lightweight properties, durability, and shock-absorption.

You can rely on our team to help you choose the tool that meets your needs, and we will take care of its safe packaging and delivery. All the orders made through our shop are trackable, and if you have any issues or questions, you can always reach out to our support team at support@forgedsteeltools.com.