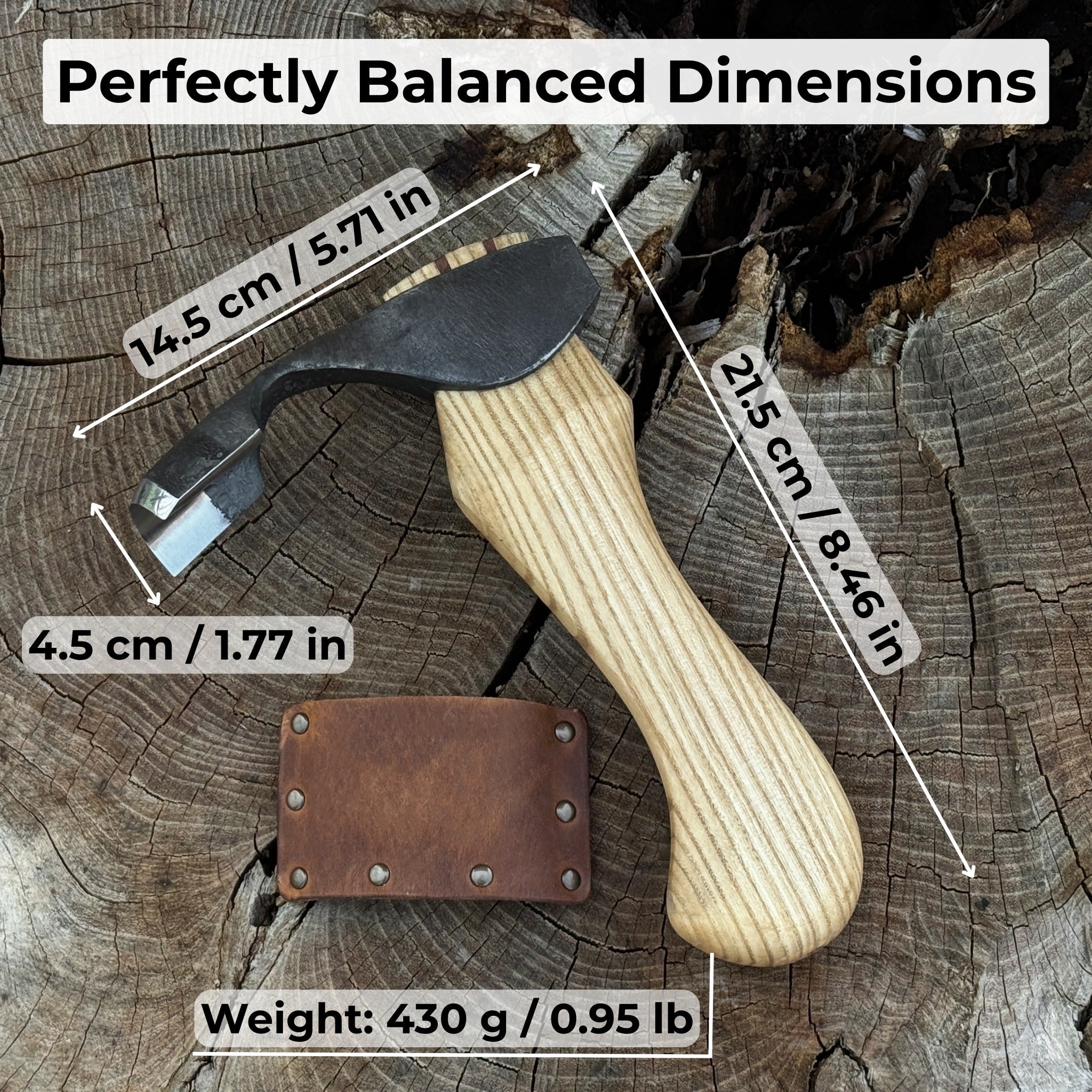

Small Kuksa Adze with Deep Curved (Round) Blade, 4.5 cm (1.8 in)

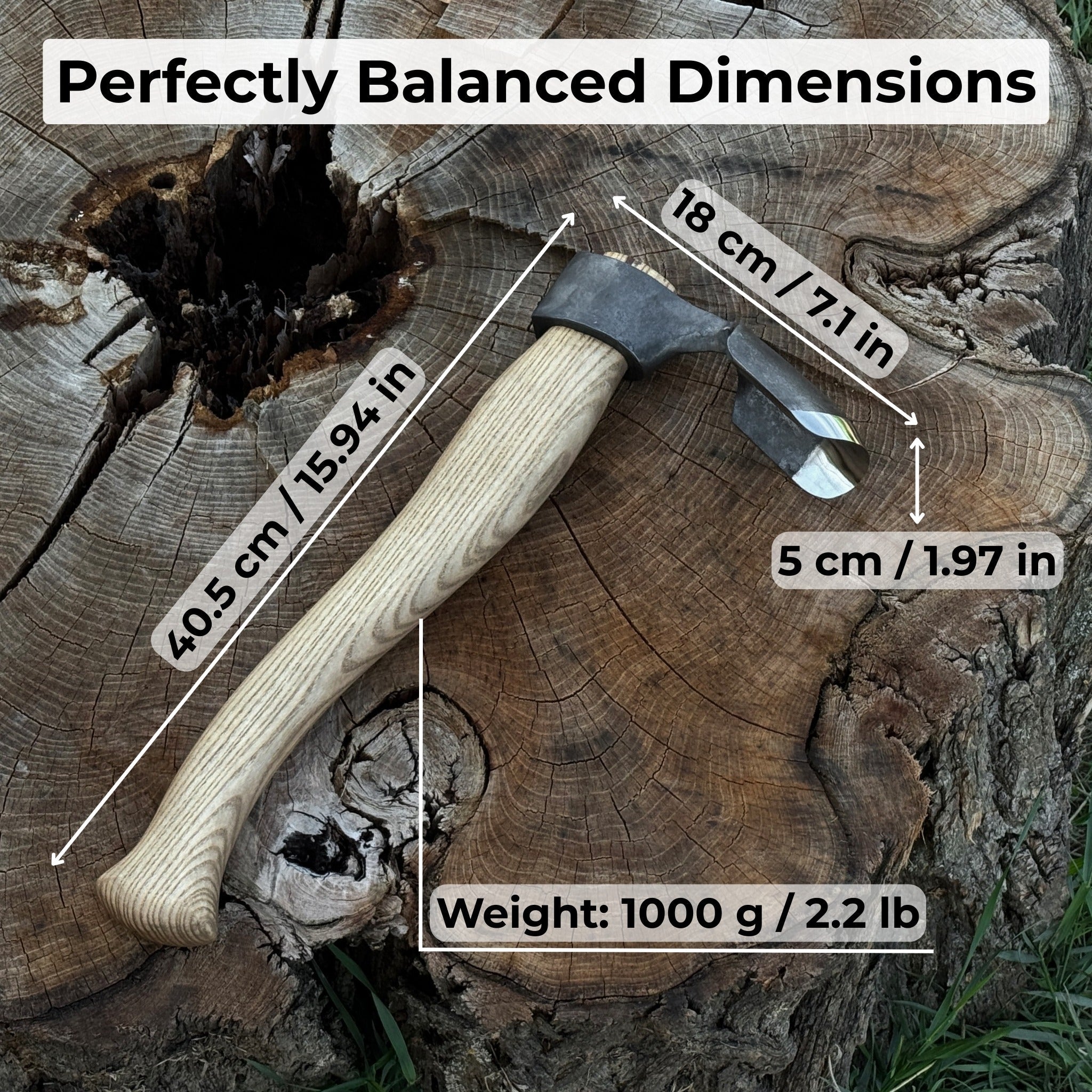

Deep Curved Bowl Adze, 5 cm (1.97 inches)

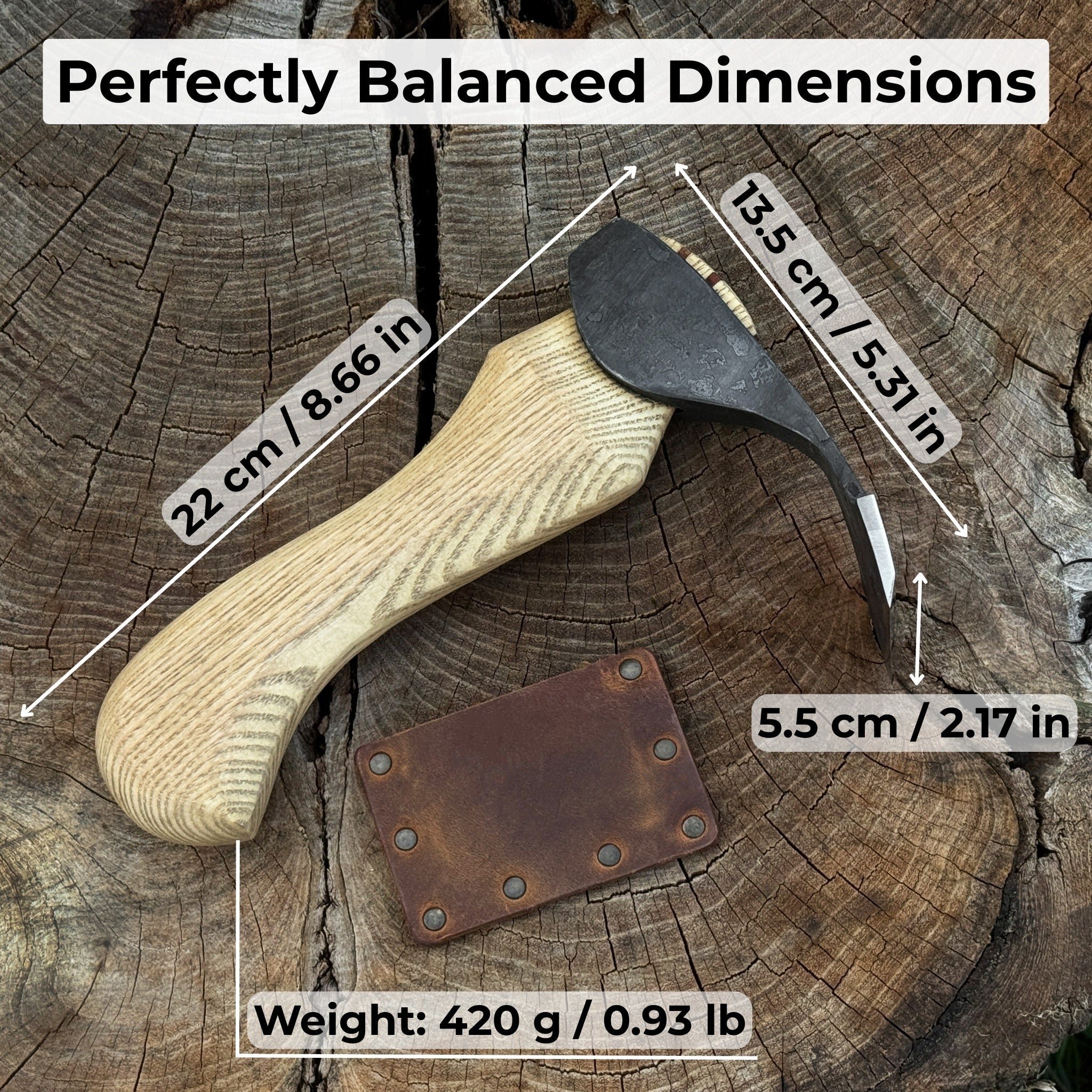

Small Adze with Straight (Flat) Blade, 5.5 cm (2.2 in)

What Is an Adze?

An adze is a versatile cutting tool primarily used for shaping wood. Similar to a chisel, this tool has ancient origins, dating back to the Middle Stone Age, around 70,000 years ago. Traditional adze uses included various tasks such as felling trees, crafting furniture, constructing buildings, and making canoes. Earlier tools were made from materials such as stone, bone, and metal, with curved wooden handles, and they were essential in the toolkits of ancient carpenters. The earliest adzes had a more hand-crafted appearance, with a rough finish resembling the tools of the ancient times.

Modern adzes are made with metal blades, often steel, and feature ergonomic wooden or synthetic handles. The head of the adze consists of the blade, the eye, and the poll. Unlike an axe, the blade of an adze is set perpendicular to the handle, making the tool better suited for shaping rather than chopping. Adzes have a dome-shaped upper side and a flat lower side, often with a clear bevel leading to the cutting edge. This defining feature of the carving adze has remained consistent throughout the centuries.

Hand adzes continue to be essential woodworking tools today. The curved blade allows for easier swinging and slicing into wood. Think of the adze as a large gouge for wood carving, designed to be used with both hands, and swung similarly to an axe, though with more controlled motion. It remains in use for tasks such as debarking and peeling logs, shaping and smoothing wood, particularly in furniture making, carpentry, and traditional woodworking such as barrel crafting (cooper’s adze), shaping staves, or crafting railroad timbers.

Types of Adzes and Their Differences

Types of Adze Blades (Straight, Curved, etc.)

Adze blades vary greatly depending on the tasks they are designed for. Blades have different cutting angles, making them suitable for versatile cutting on both hard and soft woods. A typical woodworking tool adze has interchangeable blades, meaning one tool can serve multiple purposes. Some of the most common types are:

Straight Blades: The cutting edge of the blade is flat. These are widely used in general carpentry, especially for initial shaping of large, flat surfaces like beams and boards. For example, a flat blade is used in the carpenter adze.

Curved Blades: The cutting edge of the curved blade has a pronounced curved shape, ideal for hollowing out concave surfaces like bowls. This type of adze blade is used in adze for bowl carving.

Lipped Blades: These have a slight curve at the edges, with small lips on each side of the blade. The shape resembles the letter “U”, with the lips curving towards the handle. This type is often used for spoon or bowl carving. This wood adze is created to work along the wood grain without digging in too deeply. This blade is used in adze for timber framing.

Gouge/Hollowing Blades: U-shaped blades designed for scooping and hollowing out wood, ideal for shaping bowls, spoons, and other concave surfaces.

Cooper’s Blades: Usually curved for efficient shaping of the inner surface of barrels. This adze wood tool has a sharp and robust cutting edge, tough enough for shaping hardwoods. They are often beveled on one side for more controlled cutting.

Differences in Handle Designs

A woodworking tool adze is a multi-purpose tool that can handle everything from rough hewing to carving wood, so its handle designs vary accordingly. Different handle designs offer varying levels of control and precision for cutting, smoothing, and shaping wood. A well-designed cutting tool offers an ergonomic handle design to provide better comfort, which is especially important during long carving sessions. Below are some of the main types:

- Short Handles: Used in hand adzes, these handles offer precision work for smoothing smaller surfaces. For example, an adze hoe often features a short handle since it is primarily designed for gardening and farming tasks.

- Long Handles: Found in two-handed adzes (also referred to as foot adzes), these handles are intended for powerful strokes and heavier work. The longer the handle, the more leverage it provides. Long handles are commonly used in adzes for log shaping.

- Curved Handles: These handles reduce strain on wrists and arms, ensuring a more ergonomic grip. They can be used in various adzes, from a carpenter adze to hoe adzes.

- Straight Handles: More traditional, straight handles can be found on both short and long handed adzes. They offer a simple and comfortable grip.

- Custom Handles: These are tailored to the woodworker’s specific preferences, often made from ash or hickory.

Variations in Blade Material and Quality

Blade materials affect a carving adze’s durability, performance and suitability for specific tasks. Some materials offer better resistance to moisture, while others hold a sharp edge for a longer time or demonstrate greater wear resistance. Let’s examine the various materials used for the blade:

- High-Carbon Steel: Contains a high percentage of carbon, which makes it tough and long-lasting. It stays sharp under heavy use but is prone to rust and requires regular maintenance. High-carbon steel is commonly used in woodworking adzes that handle tasks such as log shaping and timber framing.

- Stainless Steel: Resistant to corrosion thanks to chromium, nickel, and molybdenum. Though not as hard as high-carbon steel, it is easy to maintain and suitable for outdoor use. Stainless steel requires more frequent sharpening compared to high-carbon. This steel is a good choice for agricultural adzes, particularly adze hoes.

- Tool Steel: Contains elements like chromium and vanadium, offering excellent wear resistance and durability. This steel is often used in professional wood carving tools for such heavy-duty tasks as shipbuilding and log crafting.

- Alloy Steel: With added elements like nickel and molybdenum, this steel provides extra toughness and edge retention, used in industrial adzes for large woodworking projects.

Functional Capabilities of Adzes

Precision Cutting and Shaping

Adzes are favored woodworking tools for precision cuts. In addition to the blade material, the blade design, bevel angle, and handle affect accuracy. Let’s take a closer look at the types of bevels the adzes tool may have:

- Outside Bevel: Requires extra digging motion to remove material. One benefit of this bevel is that it stops adzes tool blade from cutting too deeply into the wood. This type of bevel is suitable for removing large portions of material and is relatively easy to sharpen.

- Inside Bevel: The inside bevel allows for more controlled motions. This is especially useful for the tools like a carving adze when working on smaller woodworking projects like sculpting. When swung correctly, it enables a natural wrist movement, which makes it easier to use the adze wood tool for extended periods.

- Double-Bevel Adzes: These versatile bevels are suited for general shaping and efficient material removal in different directions.

Specialized Uses for Different Types of Wood

A woodworking adze can be adapted to the characteristics of various woods. The hardness, grain, and moisture of the wood influence how effectively the adze can handle a particular task.

- Hardwoods: Known for their durability, hardwoods like oak, maple or beech are often used in construction, flooring, tool handles, and furniture. The types of wood shaping tools needed for this work require a sharp, wear-resistant blade and a steady hand.

- Softwoods: Softwoods, such as pine and cedar, are generally easier to work with. They don’t require extremely sharp blades to cut through the wood. Softwoods can also be used in construction, fencing, cabinetry, and flooring. An adze can be used to rough-shape lumber and create some joinery elements.

Grain direction is another important consideration. Cutting across the grain may require additional care and extra effort, which is why a tougher adze may be necessary. The moisture content of the wood also impacts adze use. Harder woods require sharper and more durable adzes, while wet wood is easier to cut but it may be prone to warping. Therefore, you may need a tool that cuts with high precision to prevent accidental overcutting.

Advanced Tips for Using Adzes

Like other woodworking tools, using adzes efficiently requires hours of practice. Here are some tips to help you hone your skills, no matter what type of adze you use, whether it is a wood carving adze or another type of hand adze tool.

- Sharpening regularly: A razor-sharp blade allows for smoother cutting, especially when working with hardwoods. Use a bench grinder to remove any rust first and maintain the original adze bevel angle. Hone the outer bevel by keeping it flat against the stone. To hone the inner bevel, use a ceramic slip stone. Achieve a finer finish with a leather strop. The final result should be smooth cutting without applying excessive force.

- Mastering swing control: Start with small swings to establish the angle, then apply larger swings to finish the cut. Follow the wood grain in the direction where the grain rises. If the grain runs downward, the adze will dig in, so switch directions if this happens. Watch out for knots in the wood, as the grain can change direction around them. At the end of the swing, gently push down with the adze to better control your cut.

- Customizing the handle: With more practice and improved skills, you may want to customize the adze handle to better suit your grip and style. Consider adjusting the length, curve, and thickness of the handle.

- Body positioning: Keep your back straight, and let the motions of your shoulders and arms guide the tool to prevent overcutting.

Selecting the Right Adze for Your Needs

In summary, here are a few things to consider when selecting different types of woodworking adzes for your project:

- Factors to Consider Based on Project Requirements: For finer woodworking, such as detailed wood carving, choose a small, lightweight adze that offers high precision. For heavier tasks, like framing timber or shaping logs, select heavier adzes with longer handles and broader blades. Also, align the choice of the tool with the x hardness of the wood.

- Understanding the Impact of Size and Shape for Your Needs: The size and shape of the blade and handle define the scope and type of work it can do. Larger adzes with longer handles provide more leverage and allow for more force, while smaller adzes feature shorter handles for better control over each cut. The curve of the blade determines how much material can be removed with one cutting motion.

- Common Mistakes and How to Avoid Them: Beginner wood carvers often ignore grain direction, which results in uneven cuts. To avoid damaging the material, always cut along the grain.