Half-Rounded Drawknife (Inshave) with Leather Sheath, 15 cm (5.9 inches)

Small Curved Drawknife (Push/Pull), 10.5 cm (4.13 inches)

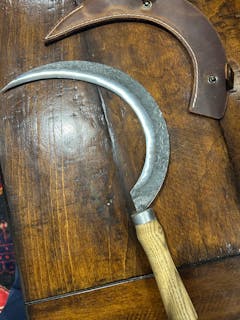

Curved Drawknife (Push/Pull), 14.5 cm (5.7 inches)

Curved Draw Knife (Push/Pull Shave), 25.5 cm (10 inch) Cutting Edge

Curved Draw Knife (Push/Pull Shave), 14.5 cm (5.7 inch) Cutting Edge

Curved Draw Knife (Push/Pull Shave), 10.5 cm (4.1 inch) Cutting Edge

3-Piece Curved Drawknife (Palm Handles) Set

3-Piece Inshave (Half-Rounded Drawknife) Set

Inshave (Half-Rounded Drawknife), 13 cm (5.1 inches)

What is a Drawknife?

Similar to carving knives, draw knives originate from ancient times when ancient artisans used drawknives made from stone and bone. Today, they are still commonly used in woodworking projects, particularly for rough wood shaping, debarking trees, splitting wood, fine detailing, such as shaping chair legs, back splats, seats, and other rounded parts.

When it comes to removing large portions of wood with precision, draw knives are unmatched. They can accomplish the same tasks as spokeshaves, but in significantly less time, and they don’t require a high skillset to use. However, the finish may not be as smooth as that achieved by a spokeshave.

The basic design of a woodworking draw knife has remained mostly unchanged, proving its efficiency and practicality. The tool consists of two handles and a long, thin blade attached to them. The size of the blade varies depending on the intended use, with longer blades often used to debark trees and shorter ones for carving fine details.

The average blade length is 8-10 inches, and it is usually designed with a single bevel, featuring a rounded or smooth edge. The handles can be positioned at the same level as the blade or below it for ergonomic benefits.

This woodworking tool is straightforward to use, allowing craftsmen to effortlessly remove large and small amounts of wood with great precision and freedom.

Types of Drawknives

The most common types of drawknives are straight, curved, and folding tools. Each has variations in blade shape, cutting edges, and an extensive range of applications. Here’s a more detailed look at each:

Straight Drawknives

Design: A straight draw shave tool features a straight blade aligned with handles on the same plane as the blade.

Blade shape/curvature: There’s no blade curvature; it is straight and flat, which limits its use to flatter, broader surfaces.

Cutting edges: Usually has a single bevel and the blade’s edge is straight across its length.

Intended uses: Straight drawknives are perfect for rough shaping, debarking, trimming down logs, and flattening surfaces. They are effective at efficiently removing material, especially bark from logs or branches.

Curved Drawknives

Design: A curved drawknife has a blade that curves inward, with handles either on the same plane or slightly lower than the blade. Handles may remain horizontal or be angled downward for better leverage during curved cutting motions.

Blade shape/curvature: The blade curves inward to facilitate deeper cuts.

Cutting edges: The edge follows the blade curvature length, typically with a single bevel on the convex side.

Intended uses: Best for removing large amounts of wood quickly, shaping rounded objects, hollowing out wood (e.g., in bowls or spoons), and refining shapes.

Folding Drawknives

Design: Folding drawknives feature handles that fold inward over the blade, allowing for compact and safe storage.

Blade shape/curvature: These knives often have straight blades; curved ones are less common.

Cutting edges: The cutting edge is similar to that of a straight knife.

Intended uses: These tools are versatile, handling diverse woodworking tasks from debarking logs to more detailed work, like creating rounded edges on furniture pieces, shaping ergonomic handles for tools, and more.

Choosing the Right Drawknife

When selecting a 2-handed draw knife, think of not just the tool’s characteristics, but also the project’s complexity, the type of material you’ll be working with, and the specific tasks the drawknife will need to accomplish. Here are some factors to consider:

Considerations for Woodworking Projects

- Type of wood: Softer or green woods are easier to work with using drawing knives. In contrast, dry (seasoned) woods are harder and require more strength and skill. Projects with long, straight grain are the best for draw knives, whereas irregular wood grain can cause the blade to catch, tear the wood, or create bumpy surfaces. You will need a very sharp draw knife for woodworking and should always consider the wood grain when shaping a piece. Examine the grain before starting a carving project, and make light cuts when approaching reversed grain or tricky areas.

- Project complexity: Projects like debarking logs or creating tool handles are ideal for beginners gaining experience with draw knives. More complex projects, like shaping chair legs or canoe paddles, require advanced skills and curved drawknives for shaping rounded surfaces. Plan your project thoroughly by mapping out project stages: rough shaping, fine shaping, and finishing.

- Skill level: Beginner wood carvers will focus more on controlling the tool and achieving accuracy in cutting. Experienced craftsmen may take on more intricate projects, such as creating furniture pieces or parts.

Blade Material and Sharpness

Blade materials always remain front and center, as they directly affect the durability and performance of drawing knives. Blades are usually crafted from these materials:

- High-carbon steel: Expertly crafted draw knives often use high-carbon steel, known for its ability to hold sharp edges for a long time. It can withstand heavy-duty tasks, but is prone to rust and requires regular cleaning and oiling. It may also require higher-grade sharpening tools.

- Stainless steel: Highly resistant to corrosion, making it more suitable for humid environments. However, it dulls faster than high-carbon steel and can be harder to sharpen.

- Laminated steel: The high-carbon core steel provides excellent edge retention, while the softer outer layers make the blade less prone to damage. The sharpening process itself is more challenging, as the core must be protected. This material is also more expensive.

- Tool steel: Extremely durable and can be sharpened to a razor-sharp edge. But sharpening it can be difficult due to extreme hardness levels, and it is also more prone to rust compared to stainless steel.

Handle Design and Comfort

Ergonomic handles provide comfortable grip, allowing woodcarvers to work for long hours without fatigue. Common handle designs and materials used for draw knife woodworking include:

- Handle designs:

- Straight handles: Traditional grip, suitable for various tasks but not the best option for fine detail work.

- Curved handles: Better ergonomics but may be less intuitive for beginners.

- Angled handles: Offer excellent leverage and control for heavy use but are not the best option for detailed work.

- Handle materials:

- Wood: Comfortable and natural but may crack if not maintained. Ash is a great choice for its density and light weight.

- Composite materials: A knife to draw with this handle offers durability and good grip but is more expensive than traditional materials.

- Rubberized plastic: Provides a non-slip grip and requires less maintenance but may become uncomfortable with extended use.

How to Use a Drawknife

To maximize efficiency in transforming rough timber into finely shaped pieces, it’s crucial to practice drawing knife woodworking techniques and follow basic safety rules:

Basic techniques:

- Position the knife to draw at a 15-30 degree angle to the wood, depending on the type of cut. Shallower angles allow for slight cutting, while steeper angles remove more wood.

- Consider the bevel direction. With the bevel side up, less material is removed, reducing the risk of mistakes. However, even a durable blade will dull faster. Using a drawing knife with the bevel side down is more common and reduces the need for frequent honing, but requires more caution from beginners, as the blade tends to dig deep into the wood.

- In drawing knife woodworking, hold both handles, either pushing the blade toward yourself or pulling it away, depending on the grain direction and desired result.

- Always follow the grain, as the drawing knife is an appropriate tool for ensuring a smooth finish.

- For finer shavings, keep the blade finish parallel to the wood surface. For deeper cuts, gradually increase the angle.

Safety tips:

- Secure the wood piece in a vise or shaving horse for stability.

- Keep the durable blade of the draw knife sharp to reduce the force needed and prevent accidental slips.

- Wear protective gear like gloves and safety glasses.

- Control the depth of your cuts to avoid damaging the wood or losing control of the tool.

- Keep fingers away from the blade’s path.

Common mistakes to avoid:

- Failing to secure the workpiece tightly.

- Not maintaining the drawing knives’ blades regularly.

- Cutting against the grain, which can cause splintering.

- Using the wrong angle when cutting.