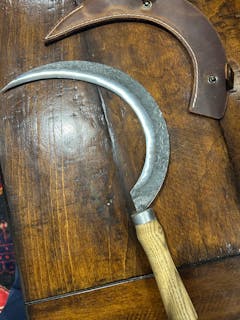

Leather Round Knife, 10 cm (3.9 inches)

Leather Round (Half Moon) Knife, 10.5 cm (4.1 inches)

Angled Leather Skiving Knife, 3 cm (1.18 inches)

Straight Leather Skiving Knife, 3 cm (1.18 inches)

Small Leather Round Knife, 8 cm (3.15 inches)

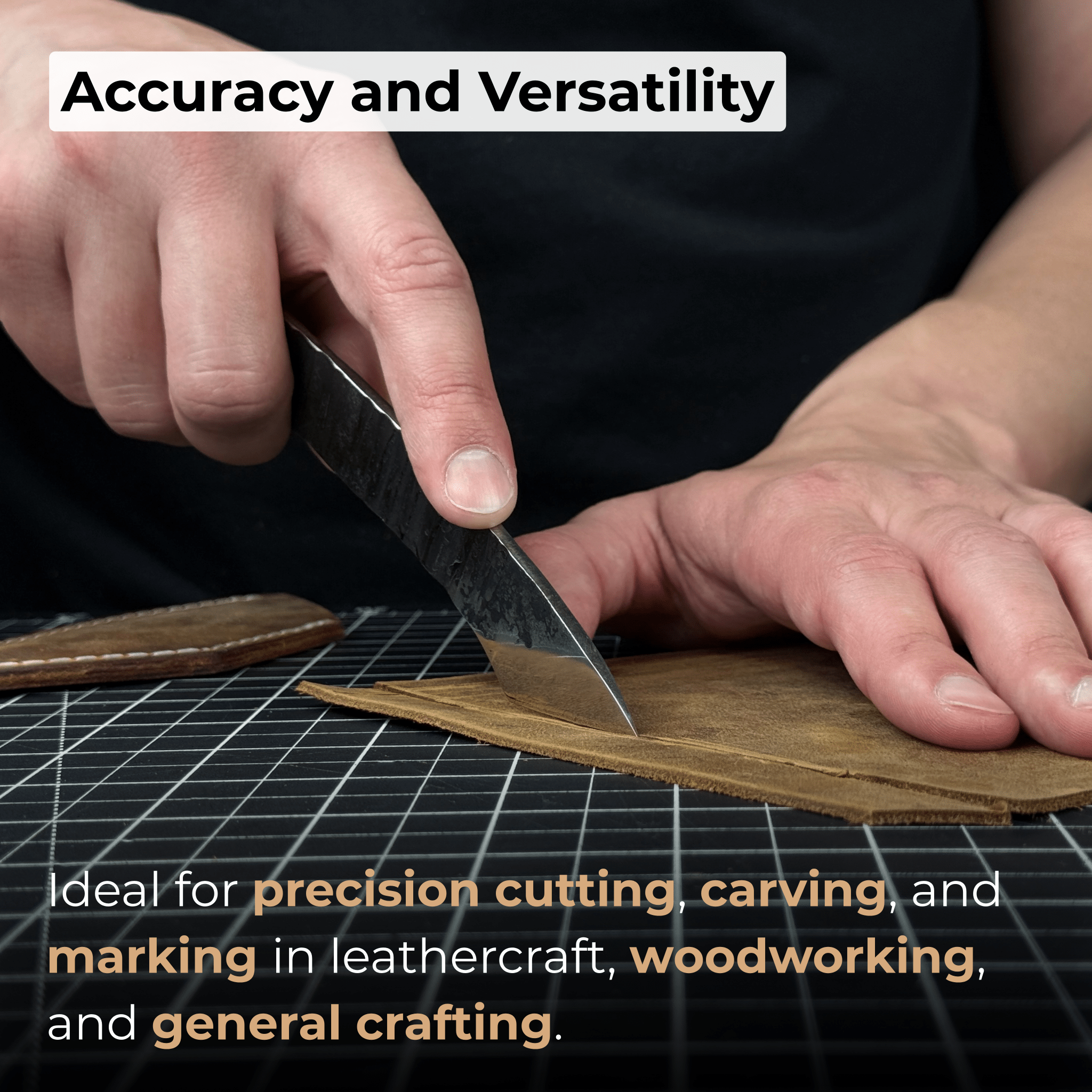

Marking Knife Kiridashi with leather sheath, 4 cm (1.57 inches)

3-Piece Leatherworking Tool Set

Marking Knife Kiridashi with Rounded Blade, 5,5 cm (2.17 inches)

Large Leather Round Knife, 12.5 cm (4.9 inches)

Marking Knife Kiridashi, 3.5 cm (1.38 inches)

Exploring the Different Types of Leather Knives

The most popular forms of leatherwork today involve making accessories like wallets, belts, and bags, along with leather carving and tooling. Both hobbyists and professionals practice these crafts, and the demand for custom products has significantly increased. Hand-stitching techniques, especially saddle stitching, are highly favored as people search for durable and high-quality craftsmanship in their daily items.

If you are new to the world of leatherwork, you may want to start with subscribing to a few experienced craftsmen bloggers and learning about their experiences using leather knives, leatherworking tools they prefer, and how they match leather types to the tools.

Knives for cutting leather are versatile. These are just some of the most common ones:

Utility Knives

Blade type: These leather knives feature straight, replaceable blades.

Material: Usually stainless or carbon steel.

Length: Around 6-8 inches, including handle.

Thickness: Thin blades, 0.5-1 mm.

Suitable for: Their sharp and straight blades cut both thick and thin leathers, helping achieve high leathercraft precision. Utility leather knives are versatile and can be used in a wide range of general cutting tasks, from detailed work and trimming leather to skiving.

Round Knives vs. Head Knives: Which is Best for You?

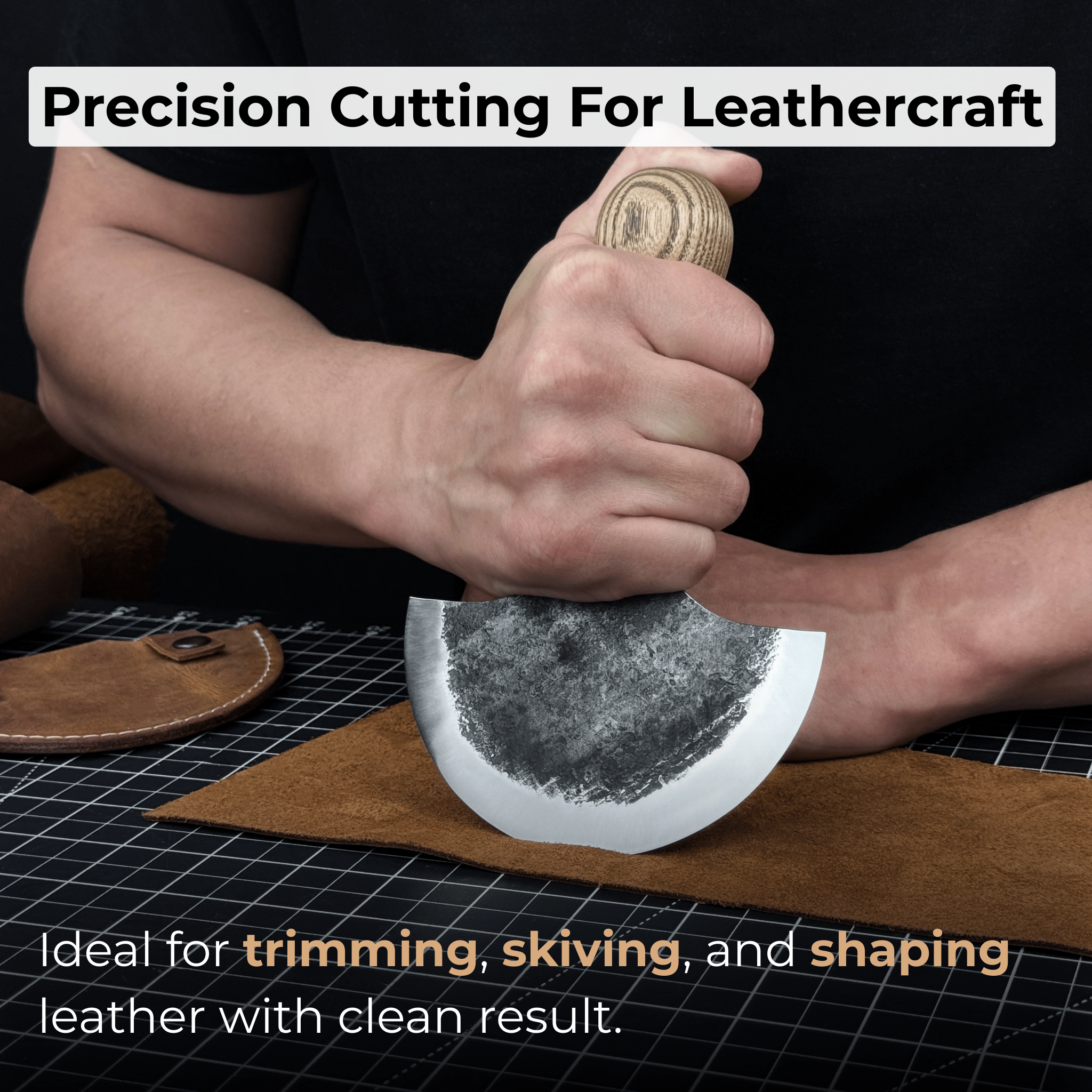

Round Knives

Blade type: Half-moon-shaped blade with a large, curved cutting edge.

Material: High-carbon steel or stainless steel.

Length: About 4-6 inches.

Thickness: Medium, around 2-3 mm.

Suitable for: Cutting large pieces of leather, skiving, and detailed work. This tool can make both straight and curved cuts, making it suitable for making smaller items like belts or larger items like bags. The round leather working knife has a large blade and requires experience to use it.

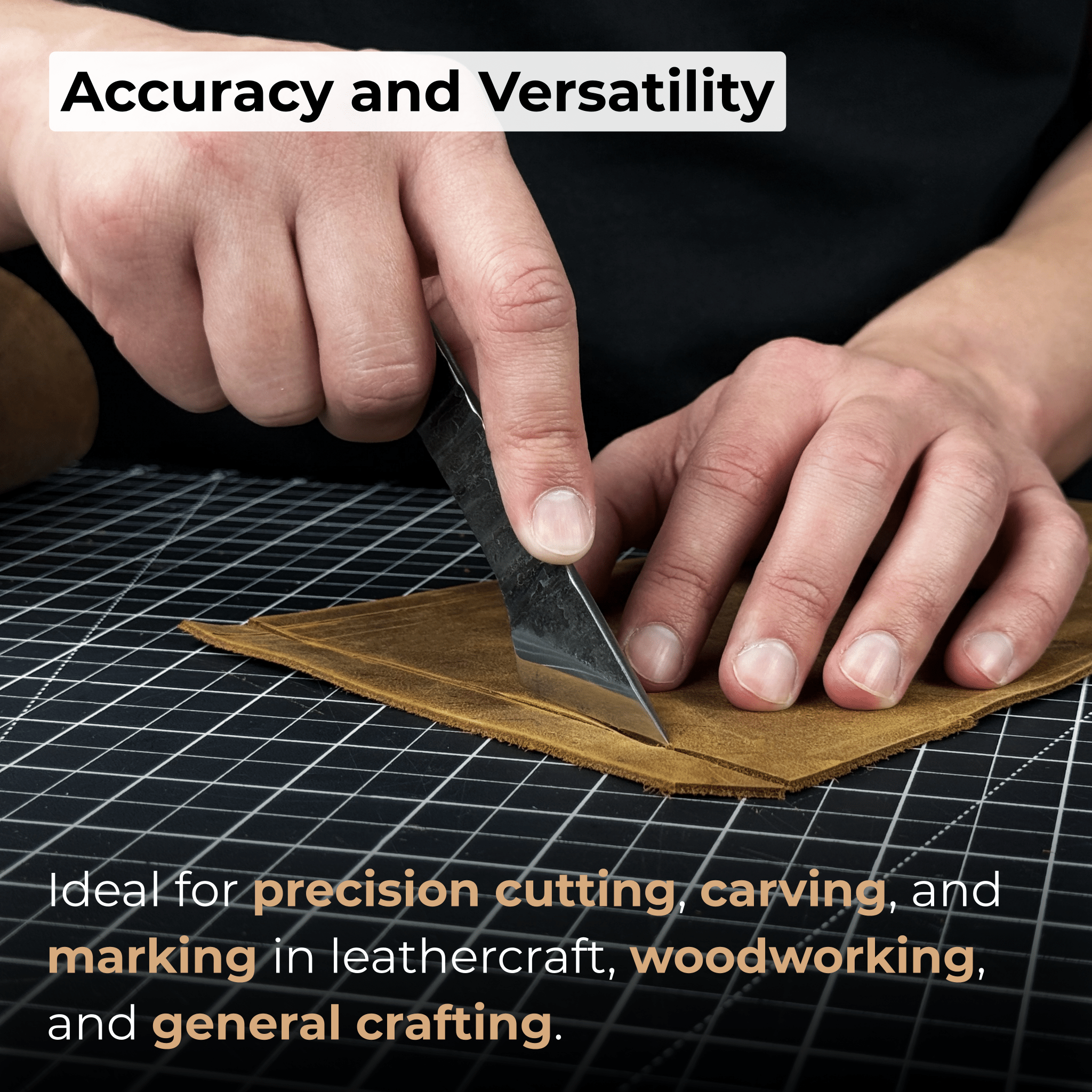

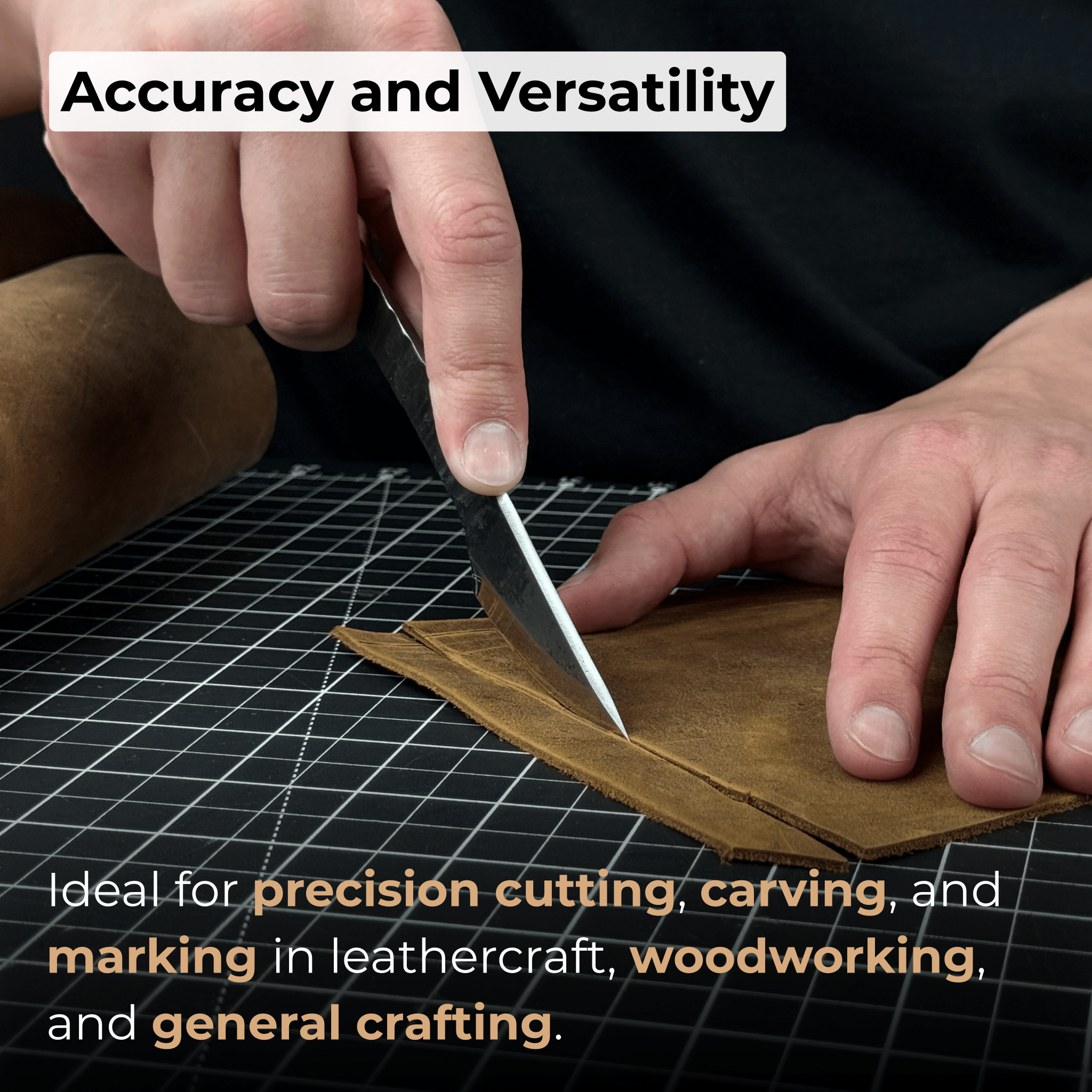

Head Knives

Blade type: More pronounced point compared to the round leather cutting knives.

Material: High-carbon or stainless steel.

Length: Blade diameter around 4-6 inches.

Thickness: Around 2-3 mm.

Suitable for: Precision cutting, detailed work, and skiving. The pointed tip of the head knife allows making intricate designs. This knife for leather is ideal for small items crafting.

Skiving Knives: Mastering the Art of Thin Cuts

Blade type: Angled, single bevel blade.

Material: High-carbon steel or stainless steel.

Length: 3-5 inches.

Thickness: Thin knife for leather with a thickness of 1-2 mm.

Suitable for: Thinning leather and reducing bulk in specific areas to make leather easier to work with.

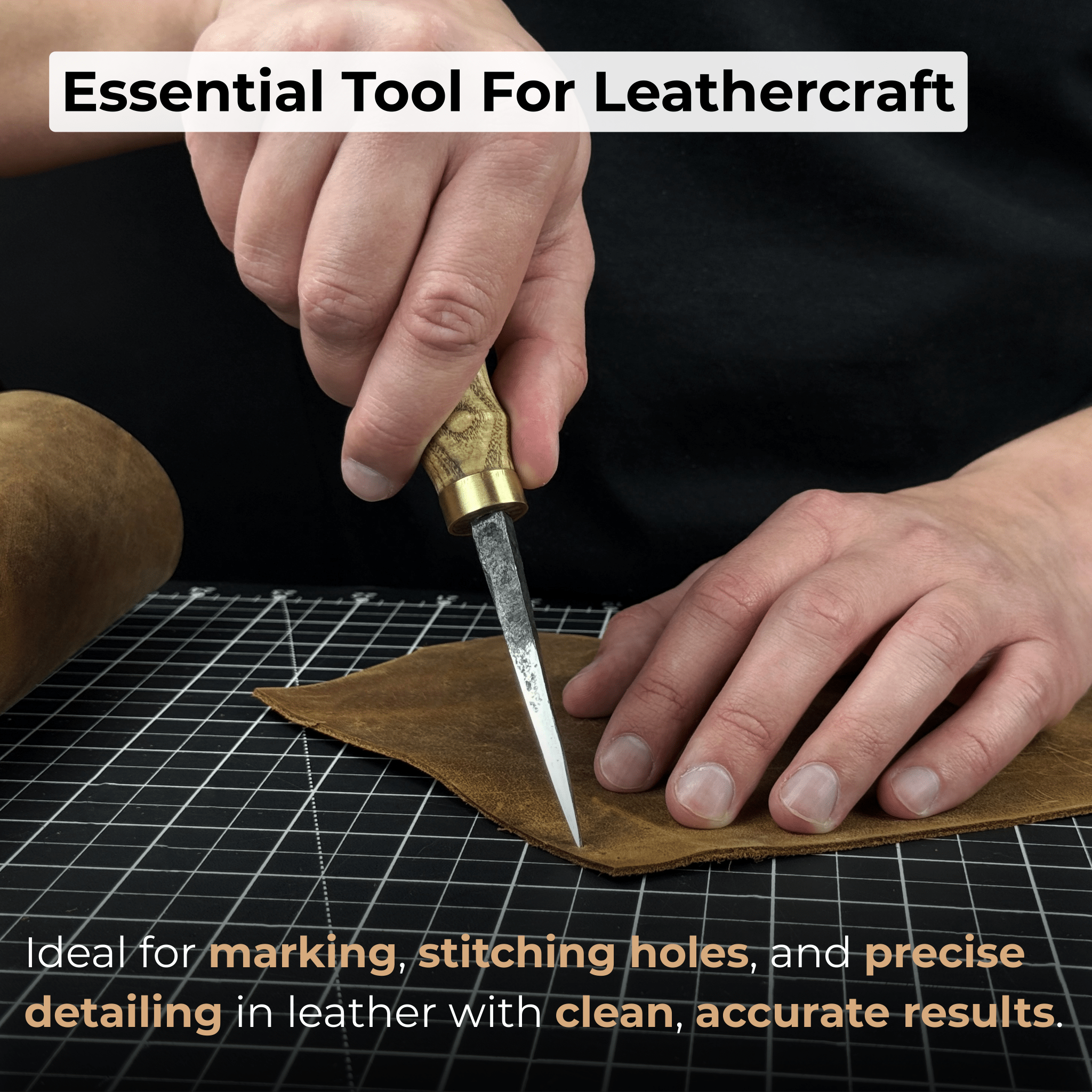

Specialty Knives for Unique Leather Crafting Techniques

Blade type: Varies depending on the specific leather cutting techniques (e.g., paring knives for thinning, bevel point knives for creating angular edges, skiving knives for tampering leather, slotting knives for functional or decorative lacing, and more).

Material: Specialty alloys, high-carbon, or stainless steel.

Length: Overall ranges from 1-6 inches depending on the type of the leather working knife.

Thickness: Overall, ranges from 0.5 to 3 mm. Thickness levels depend on the type of leather work the knives are intended for.

Suitable for: A wide range of tasks from carving to channeling and other detailed work. Each knife is designed for different aspects of leatherworking. Choosing the right tool depends on the specific items you plan to craft and the techniques you would like to apply.

How to Choose the Perfect Leather Knife for Your Craft

Matching the Knife to the Leather: Factors to Consider

Using the right leather is essential for a successful project, as it directly affects the quality and ease of your work.

Leather thickness varies, requiring different tools. Thick leather works best with sturdier knives like round, utility, or skiving knives. For thin leather, paring or detailed knives are more suitable, while bevel point or curved head knives perform well on medium-thickness leather.

Genuine leather, while budget-friendly, is often considered lower quality compared to full-grain or top-grain leather. It is usually made from leather scraps, pressed together, then glued and painted. This leather is affordable but it is not recommended for high-end handmade leather goods.

Vegetable-tanned leather is stiffer and more suitable for detailed work like stamping and burnishing. The best knife for cutting leather of this type is a skiving or round knife. It is more robust and can provide precision needed for this type of leather.

Chrome-tanned leather, on the other hand, is more flexible and less receptive to stamping and burnishing. It requires a different leathercraft technique with more robust leather cutting knives with durable blades.

The Importance of Blade Material: Steel Types and Their Impact on Performance

Blade material significantly impacts precision and cutting quality in leatherwork. The blade sharpness and durability of a knife are directly influenced by the type of steel used. Here’s a look at some common steel types and their effects on knives for cutting leather:

Carbon Steel

1095: High carbon content makes it easy to sharpen though it lacks corrosion resistance.

O1: Offers excellent edge retention and ease of sharpening but it is prone to rust, requiring regular oiling.

High-Carbon Steel

58–60 HRC: Offers excellent cutting edge retention and toughness, best suited for precision trimming of various leather types. It is durable and tough but requires regular care to prevent corrosion.

60–62 HRC: This range is highly recommended for high-carbon leather knives. It offers a good balance of edge retention and durability, can handle heavy-duty tasks.

Stainless Steel

440 C: Balances hardness and corrosion resistance. It is easier to sharpen and can be suited for general leatherwork.

VG-10: A premium Japanese steel, known for its sharpness and corrosion resistance, used in high-quality leather cutting knives.

Tool Steel

D2: Holds a sharp cutting edge extremely well, durable, suitable for performing tough cutting motions. It is more challenging to sharpen but provides great wear resistance.

M4: Known for its hardness and edge retention, great for heavy-duty work but can be brittle.

Ergonomics and Handle Design: Comfort in Long Crafting Sessions

Professional leather tools are often used during long crafting sessions, so choosing the ones that minimize strain is highly important.

Key factors in knife ergonomics:

- Handle shape: A well-designed handle reduces pressure points and offers better control.

- Material and texture: Rubber or composite materials provide a non-slip grip, with textured surfaces enhancing grip security.

- Weight distribution: A well-balanced leather knife minimizes hand fatigue and improves cutting efficiency.

- Handle size: Handles should match the user’s hand size. Ergonomic designs often come in various sizes to accommodate different hand dimensions.

Advanced Techniques with Leather Knives: Elevate Your Craftsmanship

Precision Cutting: Tips for Achieving Clean, Straight Lines

For clean, straight lines in your leather cutting, these tips can help:

- Choosing the right tool: Use a straightedge or ruler alongside your knife for leather for precise cuts.

- Proper measurement: Measure twice before cutting. Draw clear, straight lines with a pencil or fine tip marker.

- Securing material: Use clamps or weights to hold the leather in place, working on a stable surface like plywood with non-slip tape on your straightedge.

- Blade sharpness: Proper tool maintenance is essential at all times. Check leather knives’ sharpness in advance.

- Cutting technique: Maintain a consistent angle and pressure, and make multiple passes to avoid uneven cuts.

- Practice before cutting: Practice on a piece of scrap material before making final cuts.

- Troubleshooting issues: If your cuts are not straight, recheck your tools and revise your leathercraft techniques.

Skiving Like a Pro: Techniques for Consistent Thickness

Achieving consistent thickness during skiving enhances the quality and appearance of your leather projects.

- Choosing the right skiving technique: For step-like profiles, use a paring knife and skive to half thickness, ensuring smooth steps. For bevel or slope skiving, when you skive the leather into a gradual slope, use a head knife or skiving knife. In split skiving, use a French shave for thicker leather and a paring knife for more control, while reducing the overall leather thickness.

- Sharp blades: Regular skiving blade care is necessary to retain the leather knife cutting edge.

- Dampening and securing the leather: Slightly dampening the leather and securing it on a stable surface prevents tearing and slipping.

- Consistent angle and stroke: Skive at a 20-30 degree angle with smooth, even strokes.

- Checking your work: Use a caliper or thickness gauge for accurate measurements.

Maintaining Sharpness: How to Sharpen and Hone Your Leather Knife

In addition to sharpening, proper cleaning and storage are crucial for extending the life of your custom leather knives.

- Prepare sharpening stones: Wet a sharpening stone if it’s a whetstone, or use oil for oil stones.

- Sharpen at a correct angle: A 20-25 degree angle is usually recommended.

- Sharpening: Gently slide the knife across the stone in a sweeping motion. Sharpen both sides, if it’s a double-edged blade. Start with a coarse-grit stone and move to a finer grit stone. Then check the edge for sharpness.

- Stropping: Maintain a consistent angle of about 10-15 degrees and pull the blade away from the edge, avoid pushing the blade into the strop. Test the sharpness when finished.

- Regular tool maintenance: Develop a habit of regular care of your leather knives. Strop them between carving sessions, use a protective sheath to keep the blade sharp, and store leather knives in a dry place.

Caring for Your Leather Knives: Ensuring Longevity and Performance

Cleaning and Storing Your Knife: Best Practices for Leatherworkers

Sharpening alone does not ensure the longevity of leather knives; proper cleaning and storing are equally important for maintaining leatherworking tools in good condition.

Some of the best cleaning practices include wiping the blade with a damp cloth immediately after each use. Periodically, deep cleaning with a mild soap and warm water is recommended. After cleaning, it’s important to dry a leather working knife thoroughly to prevent moisture buildup. Oiling the blade is another necessary step to protect it from rust and corrosion.

Storing options are numerous. It is advisable to use a sheath to protect the blade, keep the leather working tools in a dry environment, and inspect them regularly.

Preventing Rust and Corrosion: Tips for Blade Care

The best way to prevent rust is by storing your knives in a dry place, applying a protective coating, and regularly oiling the blade (as oil dries out over time). However, experienced craftsmen recommend using Vaseline (petroleum jelly) instead of oil. Vaseline forms a sealing barrier that protects metal from moisture, the primary cause of rust. Apply a thin layer of Vaseline to the bevel and any exposed steel, and ensure the sheath is dry before storing your knives.

When to Replace Your Knife: Signs of Wear and Tear

Regular inspections of the leather working knives are essential to catch signs of wear early on and plan for tool repair or replacement. Here are the signs to watch for:

- Sharpening becomes ineffective: If sharpening no longer restores the blade, it may be time for a new knife.

- Visible chips or cracks on the blade that negatively affect the tool performance.

- Uneven blade wear will impair cutting quality.

By regularly checking for these signs and maintaining your leather knives, you will keep tools both effective and safe.